Stainless steel products catalogue brochure

The iron and steel constructions because all of the other industries, whether they be heavy, medium, or light, depend on the industry for their machinery, the industry is considered the most fundamental industry. Steel is essential to the production of many different types of commodities, including those used in engineering, building, defense, medical, scientific, and telecommunications equipment, as well as consumer items. Steel production and consumption are frequently used as a proxy for measuring a nation’s level of economic growth.

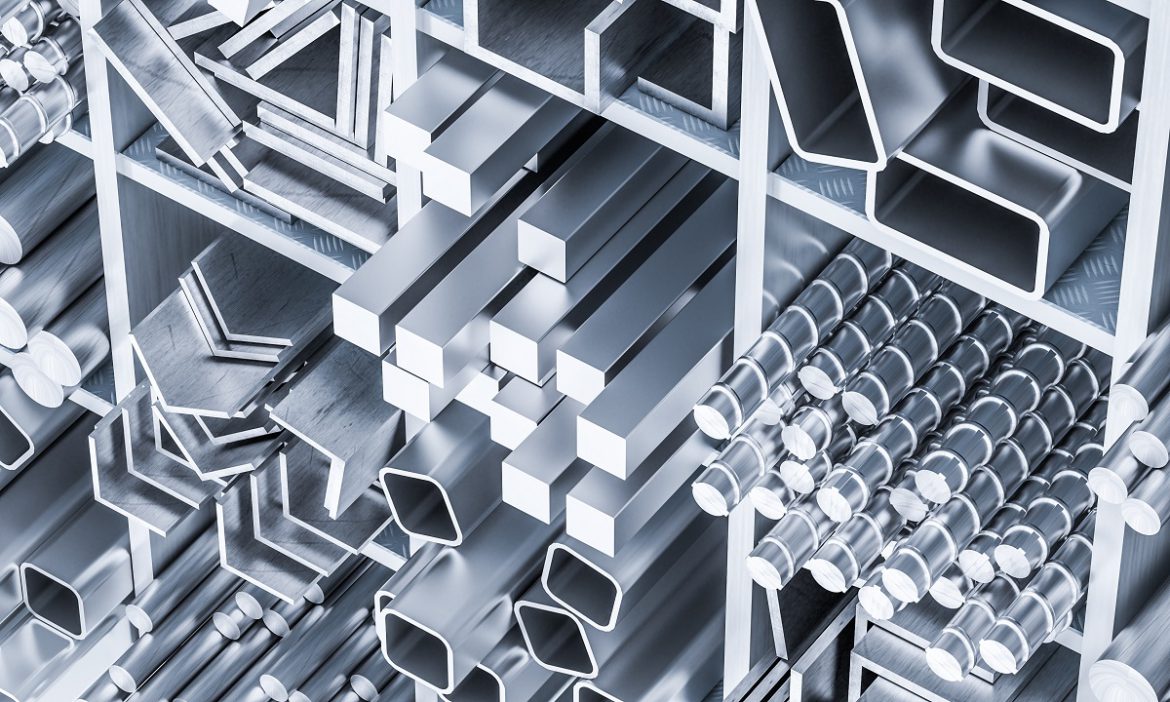

Steel products brochure

A steel brochure is a comprehensive list of a company’s steel products. It deals with the specifics of the products, such as their measurements and sizes, as well as their quality and standards. Therefore, in order to create a useful brochure, brand names must take these factors into account.

- The Four Types of Steel

Iron and carbon are the two components that come together to form steel. Steel is first separated into four distinct types, and only then is it subdivided further into grades within each of those categories. Carbon steels, alloy steels, stainless steels, and tool steels are the four primary categories of steel that are available. There are many various kinds of steel, and each one has its own set of distinctive properties that make it useful in a particular industry.

Carbon steels are the most common type of steel, making up around 90 percent of all steel produced. The amount of carbon found in carbon steel normally ranges from 0.2 to 2%.

In order to modify the properties of the metal, alloy steels incorporate a wide variety of different sorts of elements. Chromium, nickel, copper, molybdenum, vanadium, and aluminum are all elements that are commonly found in the environment.

When it comes to applications involving corrosives, stainless steel is the material of choice. To be considered stainless steel, the percentage of chromium in the steel must be between 11 and 12 percent. In order for something to be considered stainless steel, it needs to have a chromium concentration of at least 10.5 percent.

Because of the increased heat resistance and increased hardness that tool steels obtain from the alloys that they include, tool steels are frequently utilized in cutting and drilling equipment. The elements tungsten, molybdenum, cobalt, and vanadium are frequently found in tool steels.

Steel products catalogue pdf

For a compact and quick reading of a catalogue or form of a company’s steel products, the format file “pdf” is utilized. The list of steel products takes into account the many types, sizes, and particular shapes of form, with each shape being appropriate for a certain use.

Steel structure:

Learn how to form structural steel. Cross-sectioned steel makes structural steel shapes. Standardize mechanical and chemical properties.

Structural steel comes in L-beam, Z-shape, HSS shape, L-shape (angle), C-beam, T-shaped, rail profile, bar, rod, plate, and web steel open joist.

Flutes

Right-angled U-beams are like a staple. Regardless of size, both sides are the same length and parallel. Similar to angled parts; strong yet light.

Tapered flanges

Tapered I-beams exist in different diameters. Cross-sections for girders. High resistance, but not torsion (twisting).

When upright, UB Universal beams look like an ‘I’ and when angled, like an ‘H’ Building and civil engineering employ steel universal beams.

Unicolumn

Construction uses universal beams. All three I-beams or H-beams are the same length. They’re used for columns and are incredibly sturdy.

Angles

Angle steel pieces are equal or unequal. L-shaped sections have unequal axes. This part is 20% stronger and lighter. Construction, mining, and transportation use angled sections. Sizes and lengths vary.

Ovals

Circular Hollow Sections resist torsion better than tapered beams. Homogeneous beam wall density allows for multi-axis loading.

Rectangles

Like circular hollow parts, but rectangular. Mechanical and construction steel employ them. Joining and metalwork require flat surfaces.

Cubes

Like hollow parts, they’re used in columns and posts. They’re hard to bolt into beams. Box sections

Levels

Most versatile steel segment because it’s linked. They can strengthen another area. “Plates” (for example, checker plates).

Stainless steel catalogue pdf

In order to identify the type of stainless steel that is most suited for a certain application, a catalogue of stainless steel will detail the specifics of the material’s look.

People frequently refer to stainless steel as a “catchall” term when they use the term “stainless steel;” however, in reality, there are several different types of stainless steel that can be utilized for a variety of purposes.

In order to produce an entirely new substance, an alloy known as stainless steel is created by fusing together a wide variety of distinct base metals. As is the case with other types of alloys, the finished product is noticeably more robust than the sum of the individual source materials’ potential strengths.

When making stainless steel, several distinct kinds of materials can be combined in a variety of ways to produce distinctive end products. These are the following:

- Carbon

When compared to other alloys, stainless steel that has a high carbon content is significantly more long-lasting and durable. This particular variety of stainless steel is frequently used in the fabrication of cookware and utensils that are safe for consumption.

- Chromium

Chromium-containing stainless steel is much more resistant to corrosion, stains, and tarnishing than other types of stainless steel. The Gateway Arch in St. Louis is made out of this particular kind of stainless steel, and it is a well-known example of its application.

- Nickel

The incorporation of nickel into the production of stainless steel results in improvements to the material’s ability to be formed, welded, and ductilized. This not only makes it more resistant to corrosion but also makes it more durable. Nickel is what allows for stainless steel to be such a versatile alloy.

Stainless steel pipe catalogue pdf

Utilizing the pdf format version of the catalogue of information for stainless steel pipe to ensure optimal usage. Pipes made of stainless steel are utilized in the construction sector, as well as the food industry, pharmaceutical industry, petrochemical industry, automobile industry, municipal government, and decorative applications.

Extrusion and welding are two of the most common processes used in the manufacturing of stainless steel pipes. Welding is another common technique. The steel is first shaped into the form of a pipe as part of the process of welding, and then the seams of the pipe are welded together to keep the shape of the pipe once the welding is complete. The end result of the extrusion process is a product that is uninterrupted all the way through. It is accomplished by first heating a rod made of steel and then punching a hole in the middle of the rod so that it may be used to build a pipe.

Although the terms “pipe” and “tube” are frequently used interchangeably to refer to the same product, it is essential to understand the distinction between the two. Steel pipes are measured by the inner diameter (ID), whereas steel tubes are measured by the exterior diameter (OD) and wall thickness. Despite the fact that they both have the same cylindrical shape, measuring steel pipes by the ID is more common. Pipes, on the other hand, are utilized for the transportation of fluids and gases, whilst tubes are utilized for the construction of portions or components of structures.

The following is a list of some of the more typical applications for stainless steel pipe:

- Food processing

- Textile operations

- Breweries

- Water treatment plants

- Oil and gas processing

- Fertilizers and pesticides

- Chemical applications

- Construction

- Pharmaceuticals

- Automotive components

Nippon steel products

NIPPON STEEL CORPORATION is a firm that has its headquarters in Tokyo, Japan, and is engaged in the production of steel and the fabrication of steel products.

The manufacture of stainless steel involves the following six steps:

- Casting after melting

In a sizable electric furnace, the basic ingredients that make up a stainless steel object are combined and melted. During this process, intense heat is vigorously administered for 8 to 12 hours. After the steel has finished melting, it is cast into the desired semi-finished shapes. Slabs, blooms (rectangular shapes), billets (round or square), rods, and tube rounds are a few of the most popular forms or shapes.

- Forming

Second, semi-finished steel shapes are shaped. Hot-rolled stainless steel is one example (heated and passed through enormous rolls). Billets and blooms become bar and wire. Plates, strips, and sheets are cut from slabs. As stainless steel bars are most versatile, semi-finished steel shapes are often converted into them (it comes in all grades and sizes). You can use round, square, octagonal, or hexagonal bars.

- Warmth

This stage involves annealing stainless steel forms. Annealing is the controlled heating and cooling of stainless steel. This heat treatment softens stainless steel by releasing its inherent stress, making it more versatile. Even tiny variations in temperature, pressure, duration or cooling rate might cause a damaged product.

- Descaling

During annealing, stainless steel develops scale. Descaling can remove this scale. Pickling is a popular descaler.

- Cutting

This phase involves cutting the semi-finished, heat-treated, and descaled stainless steel forms into predetermined shapes. Using guillotine knives, blanking, nibbling, and high-speed blades, mechanical cutting is accomplished.

- Finishing

To assist the stainless steel product in attaining its distinctive, visually pleasing look, finishing is done. Additionally, finishes are necessary to provide the stainless steel product with a smoother, easier-to-clean surface, which is essential in sanitary applications.

steel flat products

Steel sheet/coil and steel plate are two typical names for flat steel products. These are categorized into a number of categories, such as hot-rolled coils (HRC), cold-rolled coils (CRC), steel with a metallic coating, steel with an organic coating, coil plates, and steel with a reversing mill plate. Most steel plate is produced in the 5mm to 80mm thickness range. At the lower gauges, plates overlay hot rolled coil. Reversing mill plates and coil plates are the two types of steel plates. Rolling a slab back and forth creates reversing mill plates, which are often thicker than coil plates. Coil plates, on the other hand, are created by rolling in a single direction in tandem mills.

Typically, the thickness of a steel sheet or coil is less than 5mm. Additional steel sheet goods include hot-rolled and cold-rolled sheets as well as metallic and organic coated sheets. When steel is recrystallizing, hot rolling is done at temperatures above 1700° F. Steel is easily distorted at this temperature. In comparison to cold-rolled steel, HRC offers less precision and a generally poor surface finish after cooling.

Flat steel HRC types may be marketed for a variety of uses or may undergo additional processing to produce cold-rolled coil. Typically, room temperature is used to execute the cold rolling. It improves surface finish and mechanical qualities.

CRC can be used in a wide range of contexts, mostly in the automotive and construction industries. It can also undergo additional processing to create coated steel, corrosion-resistant steel. One of the most common forms of metallic coated steel is hot-dip galvanized (HDG), which is coated with zinc to prevent corrosion by minimizing exposure to the outside environment. Organic coated steel, sometimes referred to as color-coated steel or pre-painted galvanized iron, can be produced by further processing metallic coated steel (PPGI).

The iron and steel sector is extraordinarily complex and intricate, and it is deeply entwined with the economy of the entire world. Products made of steel are utilized in a wide variety of markets, including the construction and automobile industries, amongst others in the manufacturing sector. The basic forms of raw materials and energy that are utilized by the steel industry are iron ores, scrap metal, and coal.

The availability of iron and steel must be taken into consideration by the businesses before making any decisions regarding where to obtain it, at what price, and of what quality.

We are here to make sure that the resources you have requested are provided to you in a satisfactory manner.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: