dri fines supply in bulk

Directly reduced iron , also called sponge iron, is produced by direct reduction of iron ore (in the form of lumps, pellets or fines) to iron by a reducing gas or elemental carbon produced from natural gas or coal. Many ores are suitable for direct reduction. For more information on dri fines supply visit our site.

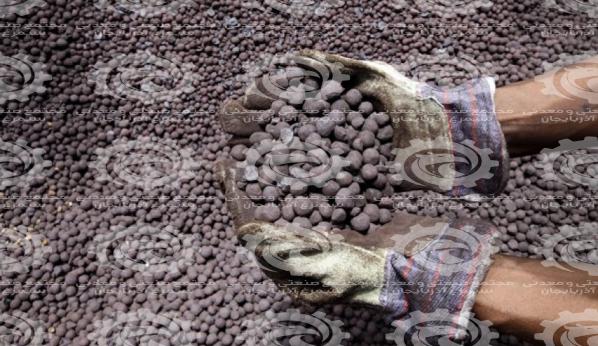

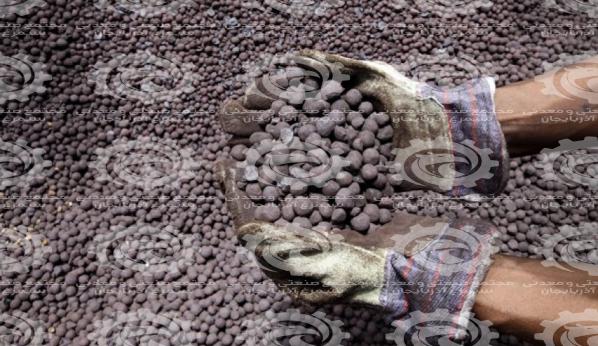

What are dri fines?

DRI fines generated during its manufacture and processing generate high content fines in the size fraction less than 2mm. It has an iron content of over 80%. It is difficult to use this type of iron-rich material directly in the primary steelmaking process without coagulation.

DRI fines generated during its manufacture and processing generate high content fines in the size fraction less than 2mm. It has an iron content of over 80%. It is difficult to use this type of iron-rich material directly in the primary steelmaking process without coagulation.

This work demonstrates the development of an agglomeration process for DRI powders for a dense metallized briquette for use as a coolant in a basic oxygen furnace. Initially, briquetting conditions such as binder, hardener, lime, powder, moisture, briquetting and curing in a batch size of 10 kg were established. Industrial scale processing followed with 500 kg batch size. Physical and chemical properties of punishments and briquettes were evaluated at different stages.

It has been found that the cold compressive strength of the cured briquette is a function of its moisture content. Processing parameters in production condition were revealed for long-term stacking of briquettes against oxidation. It has been shown that briquettes are used successfully in basic oxygen treatment.Sponge iron alone is not useful, but can be machined to create wrought iron or steel. The sponge is removed from the furnace, referred to as the inflorescence, and repeatedly hammered with heavy hammers and folded to remove slag, oxidize carbon or carbide, and weld iron together.

This process usually creates wrought iron with about three percent slag and one percent of other impurities. Further processing may allow a variety of heat treatment (eg “steeling”) by adding controlled amounts of carbon. Today, sponge iron is created by reducing iron ore without melting it. This provides an energy efficient raw material for private steelmakers who used to rely on scrap metal.

DRI fines generated during its manufacture and processing generate high content fines in the size fraction less than 2mm. It has an iron content of over 80%. It is difficult to use this type of iron-rich material directly in the primary steelmaking process without coagulation. At JSW Steel Vijayanagar, about 50 to 70 tonnes of DRI fines are produced per day with a size fraction For more information on dri fines trade visit our site.

Bulk supplying of dri fines

Bulk supply of dri fines by our company is possible and we export this product to other countries as well. Therefore, you can visit our site for more information about dri fines sale.

Bulk supply of dri fines by our company is possible and we export this product to other countries as well. Therefore, you can visit our site for more information about dri fines sale.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: