Steel ingots Domestic production in 2020

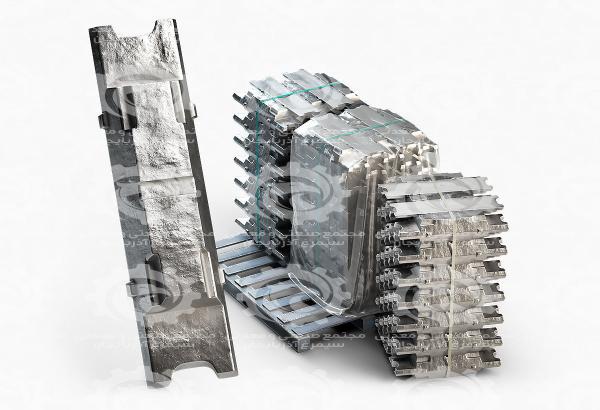

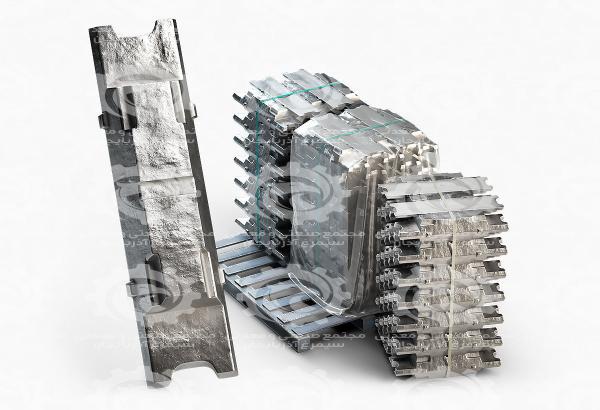

steel ingots producers have been able to make high profits by knowing the market and customer service. Steel ingots are another product of Shahr-e-Ahan, which is one of the intermediate products of rolled steel. Steel ingots are produced in two forms: Billet and Bloom. Steel ingots, which are produced in the form of billets, are also known as ingots and have a circular or square cross section.

What are steel ingots used for?

Ingot are rectangular pieces with a maximum length of 2 meters and a trapezoidal cross section. This trapezoidal cross section is easy to remove from the mold and easy to transport due to manual molding. Other names for blooms, billets or slabs in the ingot industry. The ingots have different grades, including 3SP-5SP (Russian standard), St37-St52 (German DIN standard). Some mechanical properties of ingots, such as flexibility, bending, tensile and torsion, are determined based on the amount of different elements present in steel alloys and are used in specific applications.

Ingot are rectangular pieces with a maximum length of 2 meters and a trapezoidal cross section. This trapezoidal cross section is easy to remove from the mold and easy to transport due to manual molding. Other names for blooms, billets or slabs in the ingot industry. The ingots have different grades, including 3SP-5SP (Russian standard), St37-St52 (German DIN standard). Some mechanical properties of ingots, such as flexibility, bending, tensile and torsion, are determined based on the amount of different elements present in steel alloys and are used in specific applications.

The purpose of the ingots process is due to the freezing of molten metal in the mold, and one of the intermediate processes of rolling steels (raw material for downstream industries) is two things. These goals are the shape and size of the ingot and the method of ingot in the mold and the solidification of the melt inside the mold, because the physical and mechanical properties of the final parts depend on it. After converting iron ore to crude steel or sponge iron, after steelmaking and preparation of steel melt in induction furnace or converter, steel ingot is offered as a product with different dimensions and shapes and for various applications.

Bloom and billet are commonly used in the production of beams, wires, rebars (plain and ribbed), angles and studs and shields (fabric), seamless pipes and manisman and other sections.

The use of slabs is one of the most important products of crude steel and as a raw material for hot and cold rolling processes, in the manufacture of sheet metal, plates, metal strips, coils and coils, as well as in the manufacture of welded pipes, tubes, corners and studs.

The forging process is done by two methods of continuous and manual casting (single), after obtaining the molten crude steel using steelmaking in electric arc furnace (EAF) or converter. Freezing of ingots and microstructure (internal order) of the piece is done in the casting stage, so the method of casting and molding of ingots is very important, because the physical and mechanical properties of products depend on this stage.

In this method, the melt is transferred to the molds using a ladle and remains in the melt until complete solidification. In addition, we need a separate mold to pour each ingot. CCM ingot method is widely used in industry due to its economic efficiency and speed in the process. In continuous forging, the molten metal is cooled at a certain speed inside the mold, which is usually copper and is cooled by a hydrogen system; Is poured. Meanwhile, the previous solid parts are pulled out of the end of the mold at a rate equal to the pouring speed. If the frozen ingot is continuously cut and the pouring continues as long as there is melt, the method is called continuous ingot. steel ingot weight is determined according to its dimensions and size.

Domestic demand for steel ingots

From the beginning of this year, along with the rise in the price of the dollar and subsequently the rate of inflation, we have seen a sharp rise in the price of steel products; In some products, such as rebar, this increase was more than 100%, which led to many protests. From climbing units to judicial officials and even the president who mentioned this in his last meeting with steel and petrochemical producers. By examining the reasons for the skyrocketing prices of steel products in recent months, we can make an accurate prediction of the continuation of this market and have a brief look at the price trends in the coming months.

From the beginning of this year, along with the rise in the price of the dollar and subsequently the rate of inflation, we have seen a sharp rise in the price of steel products; In some products, such as rebar, this increase was more than 100%, which led to many protests. From climbing units to judicial officials and even the president who mentioned this in his last meeting with steel and petrochemical producers. By examining the reasons for the skyrocketing prices of steel products in recent months, we can make an accurate prediction of the continuation of this market and have a brief look at the price trends in the coming months.

With the spread of the Corona virus, many predicted that, as in 2008 and 2009, when the financial crisis hit, commodity prices would fall sharply in demand and prices. At first, this prediction seemed correct. In some commodities, including steel, we may have seen price declines in the first quarter of 2020, but prices began to rise and reached pre-Cronian price levels. For example, the CIS steel billet price index for Southeast Asian countries fell by about 20 percent to about $ 370 in April from about $ 450 in mid-January, but then again rose sharply to about $ 436 in August. . There are several reasons for this market behavior, the most important of which was the decline in production at the same time as the decline in demand from steel producers. Other important reasons were the disruption of the counting and transportation of iron ore in Australia and Brazil (and thus the depletion of raw material stocks) and the implementation of large-scale economic expansion programs in China, which led to a sudden increase in demand for steel products.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: