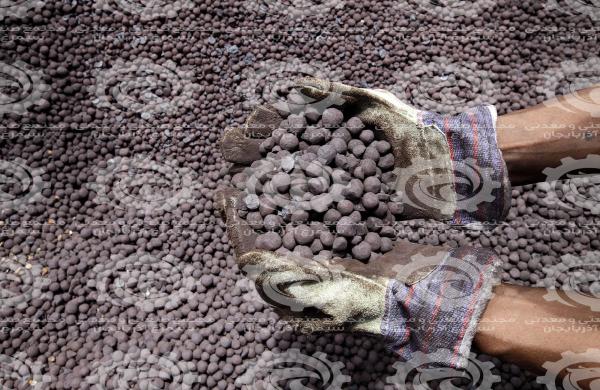

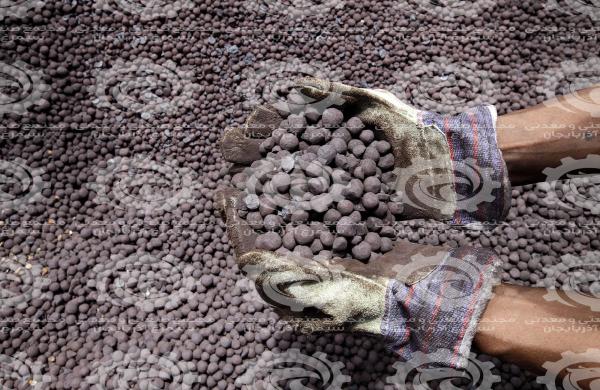

sponge iron sludge wholesalers in 2020

The pellet granules are separated after sieving with a size of less than 6 mm, which after milling can be added and recycled in iron ore concentrate to produce pellets. Foam granules of sponge iron that have been washed after reduction with regenerative gases and transferred to particle collection ponds and evaporated after evaporation in the water storage space evaporated and used to mix with other metal loads to produce pellets or agglomerates. Therefore, sponge iron sludge wholesalers in 2020 will market this product at a reasonable price.

What is metalization of sponge iron?

In general, sponge iron is the raw material for steel production and is also known as direct reduction iron (DRI). Direct resuscitation is an alternative way to solve some of the problems of conventional blast furnaces. Solid iron ore is reduced to gas at 10-800 ° C by gas (H2 + CO) or coal.

Making sponge iron is a process in which iron ore masses (typically 5 mm -18 mm in size) are placed in a sloping rotary kiln with a small amount of dolomite coal and the process takes about 12 hours in the presence of air. Before the products cool, they are magnetically separated and screened.

In general, this process requires the direct reduction of iron ore (ie, the removal of oxygen from the ore) in the solid state.

How to produce sponge iron

Iron, as a chemical element, is rarely found in pure form in nature. Iron is commonly found as an oxide in nature but is also found in the form of the carbonate, silicate, and iron sulfide. As mentioned, iron is found in nature as iron ore.

Iron ore itself is composed of iron oxides and various impurities. Impurities that come with iron ore include silicon oxide, calcium carbonate, sulfur, manganese, phosphorus compounds, and so on. Initially, different operations are performed on iron ore, such as crushing and concentrating, in order to turn it into sponge iron in later stages.

sponge iron sludge suppliers For the production of sponge iron, reduction of iron ore without smelting is done and the raw iron produced from this type of furnace is known as sponge iron. Sponge iron contains about 29 to 69 percent pure iron and is used to make steel in later stages.

Contact metal trade experts to get the price of all types of steel sections, including the price of black sheet or iron sheet, ck45 sheet, st52 sheet and other products.

In general, concentrated iron ore, limestone, bentonite, smelting aids, ferroalloys, and scrap iron are required to produce crude iron by direct reduction. Raw material preparation units use a mixture of concentrated iron ore to produce pellets.

To produce sponge iron by direct reduction methods, natural gas is used for reduction and heat supply. For this operation, methane gas is mostly used, which is converted into carbon oxide and hydrogen in three reduction units in different ways, with a sufficient amount of water vapor or exhaust gas of regeneration furnaces containing water vapor and carbon dioxide.

Due to the presence of hydrogen in the reducing gas to reduce iron oxides and produce sponge iron, the following reactions are also performed.

3Fe2O3 + H2 = 2Fe3O4 + H2O

2Fe3O4 + 2H = 6 “FeO” + 2H2O

6 “FeO” + 6H2 = 6 Fe + 6H2O

Indirect reduction units, iron ore pellets are reduced by gases resulting from the partial oxidation of natural gas by various methods such as Profer or Midrex or HYL. In the Midrex method, the iron ore pellets are cooked and sieved and transported by conveyor to the tank above the furnace.

As a result, leakage of toxic and combustible regenerative gas from the furnace is prevented. The iron ore pellets enter the furnace and are continuously reduced by reducing gas at the temperature of approximately 670 ° C. The sponge iron at the bottom of the furnace is cooled by a refrigerant gas to about 60 ° C and removed from the furnace.

buy sponge iron sludge from wholesalers

The study of sponge iron sludge export in our country shows that 20 countries welcomed Iran’s exports this year, while last year 10 countries welcomed Iranian sponge iron, so the desirable capability of this product in currency exchange and development should be given more attention. Steel industry experts have previously predicted that sponge iron exports will decline in the second half of this year, largely due to the focus of induction furnace steel plants (about seven million tonnes produced) on sponge iron instead of iron. It is scrap, because the characteristic of a reasonable price is one of the reasons for this approach. Dear customers, you can buy sponge iron sludge from wholesalers

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: