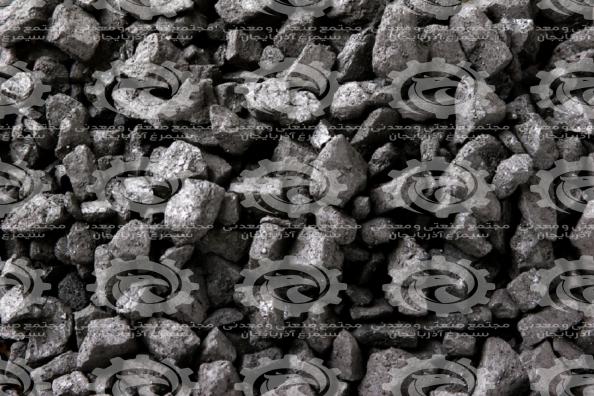

Sponge iron fines products in the global market

Today, due to the limited availability of quality scrap for steelmaking units and also the lack of uniformity of properties and chemical composition of scrap used in these units, sponge iron (DRI) has a significant share of arc furnace charge materials. For more information about Sponge iron fines products in the global market, visit our site.

What is sponge iron used for?

Major steelmakers in the country, such as Khuzestan Steel and Mobarakeh Steel, mainly use sponge iron to charge their furnaces (about 80 to 90% of the input charge to the furnace). The use of DRI with almost uniform chemical composition and low amounts of impurity elements can improve production efficiency in downstream industries such as continuous casting and rolling and lead to the production of higher quality end products. Among the properties of sponge iron that affect the performance of electric arc furnaces are: the amount of carbon available and the metallic grade of sponge iron.

The degree of metallization, or metallization, is defined as the ratio of metallic iron to total iron in the DRI. Low levels of metallic grades indicate the presence of significant amounts of iron oxide (FeO) in sponge iron. As the metallic degree of sponge iron decreases (FeO level increases), the slag volume of the structures added to the furnace (CaO and MgO) to regulate and form puffy slag increases. Thus, the useful volume of the furnace will be reduced and the amount of energy consumed will be increased, and the time from tap to to tap will be longer. Research shows that with each degree of metal DRI, furnace energy consumption will decrease by about 10 to 20 kWh per ton of melt (about 1.5 to 3%) and efficiency will increase by one percent.

Considering the effect of metal grade on different arc furnace parameters, it can be concluded that increasing each grade of DRI metal will save about $ 7 per ton of molten steel production costs. It should be noted that the effect of metal grade on energy consumption and steel production costs is not linear, but in smaller amounts of metal grade, this effect increases. Today, in modern direct reduction units, the DRI output of the reduction furnace has a metal grade of about 95%, which is very desirable for use in electric arc furnaces. However, the metal grade of sponge iron produced in direct reduction units active in Iran is in the range of 85 to 93%, which leads to a decrease in furnace efficiency and an increase in steel production costs.

The important point about sponge iron is that sponge iron has poor resistance to oxidation and abrasion, and its storage and transfer to steelmaking units will lead to a significant drop in metal grade and production of sponge iron softness and damage caused by them. These issues have created the need for sponge iron protection. Among DRI protection methods, sponge iron briquetting process has been introduced as the most effective and desirable solution that prevents the reduction of metal grade and production of sponge iron and thus can have significant benefits in improving the performance of arc furnaces, increasing the production capacity of steelmaking units and Reduce steel production costs. For more information about sponge iron grades, visit our site.

Buy sponge iron at rational price

sponge iron testing process There is actually some iron in sponge iron that is not free, in the form of iron oxide (FeO) or wustite in sponge iron. In the above example, the amount of vestite is 9% because the metallization index shows what percentage of free iron and what percentage of iron oxide is present in sponge iron, which in the above example is 9%. In electric furnaces (electric arc furnaces or induction furnaces) part of this iron oxide can be reduced and its free iron melted. For example, in induction furnaces, experience shows that about half of this iron oxide is reduced. Therefore, if the conditions for the reduction of this iron oxide are provided. For more information about Buy iron sponge at rational price, visit our site.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: