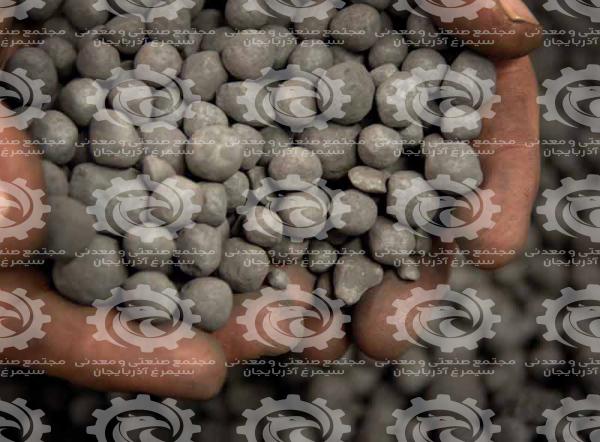

Sponge iron and scrap supplier

In order to know the price of Iranian export sponge iron ore, you can follow the site of Iranian mines and get the best type of this product. Iron ore is one of the best and most practical mineral products that can be used in various cases. This stone is marketed in various forms, including granulated, sponge iron and scrap, and concentrate.

What is the difference between sponge iron and scrap?

Minerals from which sponge iron is extracted are usually iron oxides such as magnetite and hematite, which account for 2 to 20% of the impurities. These impurities in the furnace are separated from the sponge iron and released as a pulp. Refined and concentrated ore enters the furnace in the form of powder or fine grains. The best and most suitable particle size of these grains should be between 6 and 25 mm. It should be noted that natural iron sulfide is not currently used to extract iron, and sulfuric acid is used instead.

Minerals from which sponge iron is extracted are usually iron oxides such as magnetite and hematite, which account for 2 to 20% of the impurities. These impurities in the furnace are separated from the sponge iron and released as a pulp. Refined and concentrated ore enters the furnace in the form of powder or fine grains. The best and most suitable particle size of these grains should be between 6 and 25 mm. It should be noted that natural iron sulfide is not currently used to extract iron, and sulfuric acid is used instead.

Iron is extracted from its ore during various physical and chemical processes. In the first stage, the ore must first be mined in several stages of operation, including crushing, sponge iron price, sifting, washing and using a magnetic separator, or Concentrate by the flotation method. The concentrated solution typically contains 60 to 65 percent iron, 8 to 12 percent silica. After this stage, the ore should be converted to a size of 6 to 25 mm, which is suitable for blast furnaces, which results in the occlusion of the plate.

Supplying top-grade sponge iron and scrap

Iron ore extracted in Iran is exported annually to several countries and is mainly used for steel production. By adding carbon and other elements, this stone is converted into steel, which will increase its strength and strength. Steel is an alloy that has been used in many cases from ancient times to the present day, including the construction and automobile industries.

Iron ore extracted in Iran is exported annually to several countries and is mainly used for steel production. By adding carbon and other elements, this stone is converted into steel, which will increase its strength and strength. Steel is an alloy that has been used in many cases from ancient times to the present day, including the construction and automobile industries.

Iron ore that is extracted directly from the mine cannot be used without crushing and processing, and therefore it must be processed before use. There are several methods used to process iron ore. In general, iron ore processing involves a separate step. These steps include crushing and crushing, caulking and separating the liquid from the solid. Each of these steps is sponge iron grades in a special way, and it must be done by specialized people and using up-to-date devices. Iron ore processing is one of the most sensitive measures that must be done after extraction in order to have access to high quality and unique products.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: