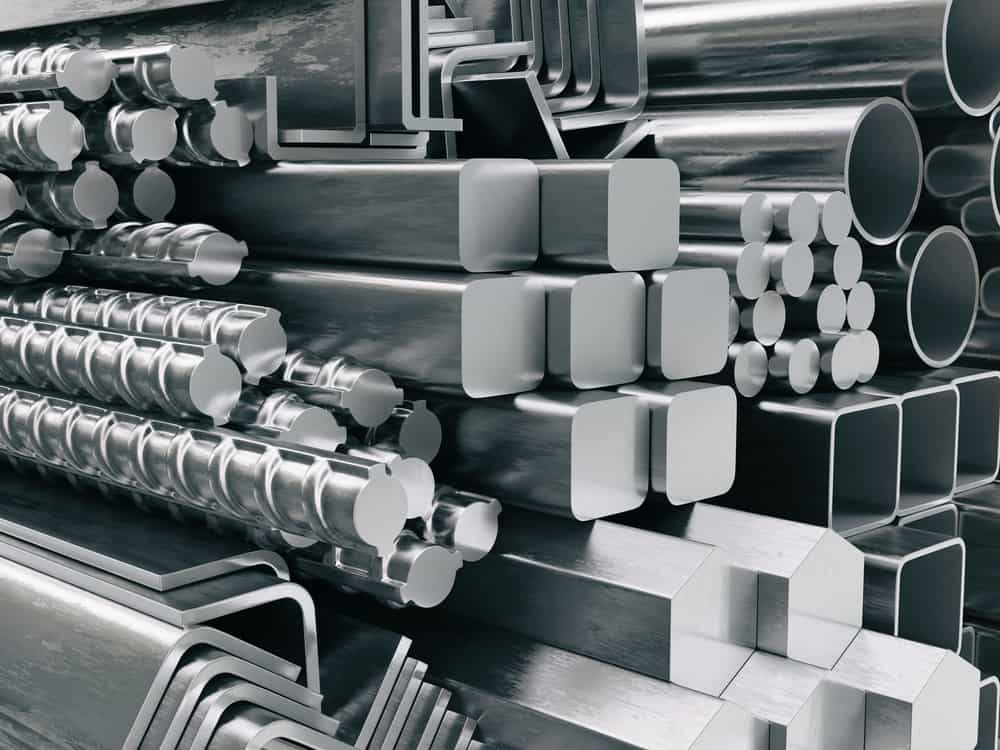

reinforcing steel types and specifications

We are in a time of incredible advancement when human ingenuity and technology are fueling unheard-of improvements in global development. This transition involves both technology and the materials that make up our world. We have an inherent stake in this and a clear obligation in our position as the top mining and Steel Corporation in the world. For the success of our world in the future, steel is as important as ever. It will be essential in creating the circular economy of the future because it is one of the few materials that is entirely recyclable and reusable. Steel will keep developing, and become smarter and more environmentally friendly.

Our company’s mission is to use smarter steel to contribute to the creation of a better world. Steels are produced with cutting-edge techniques that are more effective, require less energy, and emit a considerable amount less carbon. Reusable, stronger, and cleaner steel. Infrastructure made of renewable energy and steel will support societies as they change throughout this century.

By putting research and development at the core of our business operations, we promote this culture of innovation. Engineers that work for us because they get to take on the most challenging challenges are some of the smartest and brightest people in the industry.

We never concede that the boundaries of our material have been reached since we are motivated by an entrepreneurial spirit and a quest for perfection. When it comes to creating technology to lessen the carbon footprint of steel, revolutionizing the built environment with our new building solutions, or implementing sophisticated automation across our operations, we’ll keep pushing the envelope. The steel industry of the future needs to have these qualities.

types of steel reinforcement bars pdf

There are primarily four types of steel reinforcement bars used in concrete buildings. They are:

- Bars of Hot-Rolled Deformed Steel

- Bars of Cold-Worked Steel

- Low-alloy plain bars

- Steel Bars for Prestressing

- Deformed Hot Rolled Bars

The most typical type of steel reinforcement for R.C.C. structures is hot rolled deformed bars. The reinforcement is hot rolled, as the name suggests, which causes some deformations on its surface in the shape of ribs. These ribs aid in the concrete’s ability to adhere to them. Hot-rolled deformed bars typically have aield strength of 60000 psi.

- Bars made of cold-worked steel

By allowing the hot rolled steel bars to go through cold working, one can create a cold worked reinforcing bar. The twisting and drawing of the bars will take place during the cold working process. The procedure is carried out at ambient temperature. When compared to hot rolled steel bars, cold wrought steel bars are less ductile because they do not go through a plastic yield.

- Plain Bars of Mild Steel

The surface of the mild steel plain reinforcing bars is devoid of ribs. They have a flat exterior. These bars are employed in modest projects where the economy is the main issue. These bars’ tensile yield strength measures at 40000 psi.

- Steel Bars for Prestressing

Steel bars employed as strands or tendons are the prestressing steel reinforcement. The prestressing activity in concrete is carried out by the use of several strands. The strands are constructed from numerous wires, either 2, 3, or 7. These cold-formed wires have a high tensile strength of between 250000 and 270000 psi.

eurocode reinforcement steel grades

The ductility of the reinforcing steel determines which of the three separate classifications, A, B, and C, are recognized by Eurocode 2. Design standards have recently been updated to acknowledge the significance of the ductility of steel and provide designers with the ability to make use of the greater ductility offered by high ductility steel. The British Standard for reinforcing steels, known as BS 4449, has been updated to reflect Eurocode 2’s three ductility classes. This revision was made in connection with the publication of the new European Standard, known as BS EN 10080, which will be used in tandem with BS 4449. Additionally, the characteristic yield strength has been enhanced all the way up to 500 MPa, having previously been 460 MPa. B500A, B500B, and B500C are the three grades that were presented in the BS 4449:2005 standard.

One can think of the yield strength and the tensile strength of a certain rebar grade as the lowest and maximum stress ranges for that grade. The amount of stress that a material can withstand before it begins to irreversibly distort is referred to as the material’s yield strength. On the other hand, tensile strength refers to the highest amount of stress that a material can withstand before becoming irreparably damaged and eventually breaking.

Rebar grades are set by ASTM. The grade designation corresponds to the minimum yield strength expressed in kilograms per square inch (KSI). The numbers 40, 60, 75, 80, and 100 are frequently used as grades. The yield capacity of the rebar is reflected in the terminology that describes the grades. For instance, the minimum yield strength of grade 40 rebar is 40 KSI, which is equivalent to 40,000 PSI. On the other hand, the minimum yield strength of grade 80 rebar is 80 KSI, which is equal to 80,000 PSI.

properties of reinforcing steel bars pdf

- The following are some of the properties that define an optimal reinforcing material:

- It ought to be readily and affordably accessible in large quantities.

- It should have high tensile stress and flexibility at the same time.

- In order to reduce the effects of thermal stress, its thermal coefficient of expansion should be close to or identical to that of concrete.

- It should have a long life and be durable so that it can continue to be of use for a considerable amount of time.

- It shouldn’t have any loose mill scales, corrosion, or paint on it because those things weaken the binding.

- It must be able to make a perfect bind or grip with the concrete in order for the stresses of one material to be transferred to the other.

Metal Steel Used as Reinforcing

Due to its following characteristics, steel is frequently employed as a reinforcing material.

- It is springy and has high tensile strength.

- Its thermal coefficient, or and respectively, is almost equivalent to that of concrete.

- It establishes a strong bond with concrete.

- Bulk quantities are simply and affordably accessible.

- When comparing all the factors, it is affordable.

Twisted and Deformed Bars

The development of bonds is significantly influenced by the smoothness and roughness of the surface of the reinforcing bars. On a flat surface, fewer bonds form since there is less friction. On the other side, a better connection is provided by a rough surface. Before usage, the surface of reinforcing bars is roughened to achieve this.

Deformed bars

These bars have some sort of protrusion that serve as concrete keys and prevent the flipping of the bars. The bar creates a stronger connection by mechanical resistance to sliding because the deformations are distributed evenly along the bar.

steel reinforcement details

Rebar, short for reinforcement bar, is a steel bar used as a tension device in reinforced concrete and reinforced masonry constructions to help strengthen the concrete under tension. It is also known as reinforcing steel or reinforcement steel when it is massed. Concrete has good compressive strength but poor tensile strength. Rebar greatly boosts the structure’s tensile strength. A continuous series of ribs, lugs, or indentations are present on the surface of the rebar to improve concrete bonding and lessen the possibility of slippage.

The most used rebar material is carbon steel, which is normally made of hot-rolled round bars with embossed deformation patterns. A concrete structural part reinforced with steel will experience little differential stress when the temperature changes because steel and concrete have comparable coefficients of thermal expansion.

Other easily accessible rebar varieties include composite bars made of glass, carbon, or basalt fibers as well as stainless steel-produced rebar. Additionally, an epoxy resin that is made to withstand the effects of corrosion, particularly when utilized in saltwater conditions, may be applied to the carbon steel reinforcing bars. Bamboo has proven to be a practical substitute for steel reinforcing in concrete construction. These alternative varieties are frequently employed in specialist buildings since carbon steel does not meet their physical requirements because it is more expensive or may have less desirable mechanical properties.

reinforcement steel types

Types of Steel Reinforcement Bars:

HOT-ROLLED DEFORMED STEEL BARS:

Hot-rolled deformed steel bars are a common RCC reinforcement. In industries, hot rolling deforms the surface with ribs so it can frame concrete bonding. The stress-strain curve shows a yield point, a plastic stage where strain increases without tension, and a strain solidifying stage.

COLD WORKED STEEL BARS:

Cold-working hot-moved steel bars create cold-worked reinforcement bars. Twisting and drawing are involved and Room temperature is used. Raw-worked steel bars have less flexibility than hot-rolled bars because they lack plastic yield.

MILD STEEL PLAIN BARS:

RCC slab beams, etc. use mild steel bars for tensile stress. Plain steel bars with diameters from 6 to 50 mm. Long rods can be cut and twisted without damage.

DEFORMED STEEL BARS:

Rebars can be deformed. It has winding, herringbone, and crescent-shaped ribs. High-quality deformed reinforcing steel bars can be used as a prestressed strengthening bar after cold drawing. Due to its versatility, it’s used in many construction industries.

PRESTRESSING STEEL BARS:

Prestressing cables or tendons are comprised of numerous standards, which are thus included of different wires of average seven-wire strand consists of seven wires hectically spun together into a strand. These wires are cold-drawn and have exceptionally high tensile ultimate strength. Their high rigidity makes it conceivable to prestress concrete considerably after experiencing various losses successfully. These are utilized in prestressing solid like RCC braces of scaffolds.

types of reinforcement bars in concrete

Cement concrete 5 reinforcement bar types are mentioned below.

Hot-rolled warped TMT Bars RCC uses TMT Bars for their tensile strength. TMT Bars’ ribs increase cement bonding. Best quality TMT Bars have 64000 PSI tensile strength.

Cold-rolled steel

Cold-rolled steel bars are made at room temperature yet look like hot-rolled bars. Weak, pliable bars. Cold some buildings still use rolled bars. 60000 psi tensile.

M&Ms

This spherical bar lacks ribs. Mild steel is used in RCC beams, slabs, etc. 40000 psi tensile. Mild Steel Bars are low-quality and don’t bind well with concrete, thus they’re employed in cheap projects.

Twists

Twisted steel bars form prestressing tendons. A strand has seven wires. 270000 psi Twisted Steel Bar. These reinforce RC concrete on scaffolds. Tensile strength enables it.

Steel weld

Welded Steel Wires are mesh. It’s medium-tensile. Partitions, fencing, etc. use these. It comes in different diameters and is stronger than mild steel bar, thus it’s extensively used in construction for efficiency.

TMT bars are highly tensile. Flexible, sturdy TMT Bars. It protects against earthquakes, floods, etc. Steel seems to be utilized in some capacity across the board in our civilization. To cite a few examples of its widespread use, steel is widely used in the construction of a wide range of things, including but not limited to homes, schools, and hospitals as well as bridges, cars, and trucks. Steel is essential to the shift to a new energy source since it will be needed in varying amounts for the building of wind turbines, solar panels, dams, and electric vehicles. Furthermore, steel will be a key element in the next energy revolution. Steel consumption has increased more than threefold globally since 1970, and it is projected that this trend will continue as economies continue to expand, urbanize, become more consumer-oriented, and boost their infrastructure spending.

This valuable metal, its derivatives, and the finished and semi-finished products made from it are all supplied and provided by us. We are the supplier and provider now with our years of professional experience. To make a purchase or get assistance, all you have to do is complete the enquiry form.

Screen Recording 2022-12-19 at 1.21.22 PM (2)

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: