Made from natural iron ore before it reaches the melting point, sponge iron is a raw material for making iron and steel, which is also high in content. To make

The term “iron plate” refers to any type of metal that can be converted into flat pieces of varying thicknesses. Metals used in the iron plate industry include

The export of iron and steel products, including rebars, to producing countries is one of the most important and effective economic activities in these countrie

Sponge iron sludge is a functional product that plays an important role in the growth of the steel industry and has a thriving market share.Iran is one of the e

Today, the correct disposal of sludge is one of the major problems in treatment in all countries, both developed and developing. One of the options for disposin

As a matter of fact, Iron ore is known as a mineral substance which, as heated in the presence of a reductant, can yield metallic iron in particular. It will al

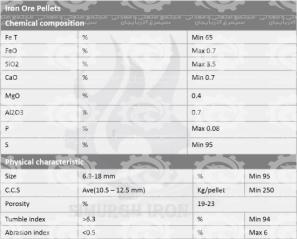

As a matter of fact, Iron pellets are tiny balls of iron ore which are utilized in the production of steel specifically. Besides, they are made with technology

Hot Sponge Iron (HBI) Briquette is a product that is produced in the Hot Sponge Iron (HDRI) process at temperatures over 650 degrees Celsius. This type of briqu

Various methods are used to produce sponge iron.

Among these methods, we can mention the MIDREX method and the HYL method. Among these two methods, the Midrex

As a result of processing natural or processed iron ore without reaching the melting temperature, sponge iron is obtained. Sponge iron is used to produce high q

D

The sponge iron production process takes place by removing oxygen from the iron ore. The quality of the sponge iron is mainly determined by the percentage of

Ore is introduced into blast furnaces along with coke (as a reducing agent). The molten material will then be injected into oxygen furnaces to make steel and re

Stainless steel (rebar made of stainless steel) High strength, corrosion resistant in recent years for reinforcing concrete in bridges, highways, buildings and

Due to the use of rebar, the selection process for alloys should start with an assessment of the requirements for mechanical properties. ASTM A955 standard spec

The high capacity hematite mine and allogist in the field of hematite iron ore extraction and processing started their activities in 1394 and now have new metho

Non-magnetic stainless steel rebars have been used in the founding of electric motors and in the construction of buildings with MRI and similar equipment. Desig

Converting other iron oxides to magnetite can improve the economics of enriching other oxides. Converting other iron compounds to magnetite, especially in the f

There are several types of iron ore, the main ones of which are magnetite and hematite. In Iran, miners have not shown much interest in investing in this area d