Iron ore concentrate price in recent years

iron ore concentrate price has been increasing in recent years. All buyers from all over Iran can buy their required hardware in part and in bulk from this market. The order registration method is such that you can receive the price of hardware in real time in person or in addition to registering your order in real time.

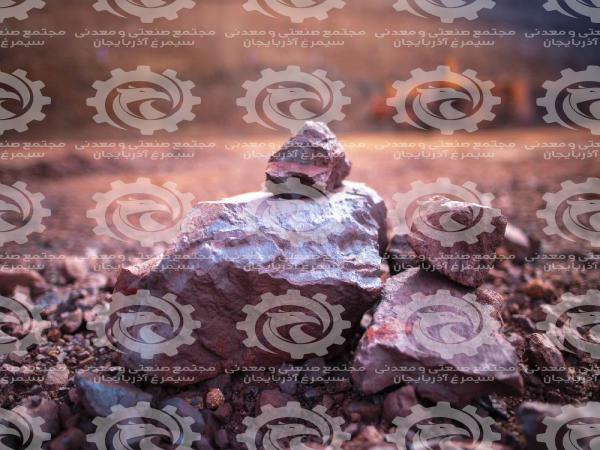

How is iron ore mined?

The ores from which iron is extracted are mostly in the form of iron oxides, such as magnetite or hematite, which are associated with 2 to 20% of impurities (such as silicates and aluminates). These impurities are removed from the iron in the furnace as pulp. The refined and concentrated ore enters the furnace in the form of powder or fine grains. The most suitable particle size is between 6 and 25 mm. It should be noted that today natural iron sulfide (pyrite) is not used in iron extraction, but its main use is in sulfuric acid.

The ores from which iron is extracted are mostly in the form of iron oxides, such as magnetite or hematite, which are associated with 2 to 20% of impurities (such as silicates and aluminates). These impurities are removed from the iron in the furnace as pulp. The refined and concentrated ore enters the furnace in the form of powder or fine grains. The most suitable particle size is between 6 and 25 mm. It should be noted that today natural iron sulfide (pyrite) is not used in iron extraction, but its main use is in sulfuric acid.

Primary processes of iron extraction

Extraction of iron from its ores takes place under special conditions through physical, mechanical and chemical processes.

In the initial stage, the steel sheet sizes must be concentrated during several stages of operations, including: crushing, grinding, sieving, washing, using a magnetic separator or by flotation. The concentrated solution usually contains 60 to 65% iron and 8 to 12% silica. After inoculation of the ore, it should be converted to a size of 6 to 25 mm, which is suitable for feeding blast furnaces, which is called agglomeration.

Extraction of iron from its ores is mainly done using blast furnaces, which are in fact a large chemical reactor in which a mixture of limestone, iron ore and coke coal is heated.

Raw materials required for iron extraction

Iron ore

In the presence of coal, it is regenerated by heat in a furnace and then melted by a stream of hot regenerating gases produced by burning coke in the hot air below the furnace and moving in the opposite direction of the iron path. Molten iron and ore pulp are discharged from the kiln every two to four hours. If the raw materials are continuously imported from the top of the furnace, then the furnace can work continuously. The product of a blast furnace is cast iron, which must be modified to convert it to other iron derivatives, especially steel.

Coke Its structural characteristics are: fixed carbon 85 to 90%, ash 5 to 13%, moisture up to 8%, volatiles 1.6 to 11%, and sulfur 0.5 to 1.2%. The role of coke in the process of blast furnaces is to produce reducing gases and is done by burning at the bottom of the furnace and its mechanical strength is also important in practice. The size of the flea used should be between 1.5 and 75 mm.

Limestone

To help melt and lower the melting temperature, impurities are added to the ore. The ratio of base constituents in the mixture (CaO) and (MgO) to acidic constituents (SiO2) must be kept constant so that the foamy and light pulp (cesium and magnesium silicates) is fully formed and other impurities accompany it. Separate from iron. For this purpose, limestone and dolomite are used. Sometimes some silicate is added to control the composition of the current pulp. The most suitable size of this material for blast furnaces is between 70 and 75 mm.

Latest price of iron ore concentrate in 2020

The outbreak of the Corona virus has created adverse conditions in the global iron ore market due to supply disruptions in Brazil and different demand trends in China and other parts of the world. Rising imports to China and declining demand from other countries in 2020 have polarized global iron ore trade. Given that China’s steelmaking profit margins have improved slightly since the first week of October, high-purity iron ore premiums also appear to be high in the final quarter of the year, as domestic supply of iron ore concentrate remains high. Coke prices have fallen in China.

The outbreak of the Corona virus has created adverse conditions in the global iron ore market due to supply disruptions in Brazil and different demand trends in China and other parts of the world. Rising imports to China and declining demand from other countries in 2020 have polarized global iron ore trade. Given that China’s steelmaking profit margins have improved slightly since the first week of October, high-purity iron ore premiums also appear to be high in the final quarter of the year, as domestic supply of iron ore concentrate remains high. Coke prices have fallen in China.

This came after iron ore prices peaked in recent years in the third quarter, thanks to growing Chinese demand and limited supply from Brazil. However, the difference between the price index of purity iron ore was 62% less than Fine Plats and other purities of iron ore, which indicated an improvement in supply and increased competition between different purities.

As a result, Chinese steelmakers in the last three months of the year have a more economical mix of types of sheet metal ore needed for their production than earlier in the year to better manage their steel production costs. In the second half of 2020, high and low purity iron ore prices came closer to the Platts price index. The performance of different types of iron ore depends on its supply and different purities, profit margins of Chinese steelmakers and iron ore mixing methods by factories. Usually, the high profit margin of premium iron ore increases the high-purity than the average, and the discount of the iron ore increases the low-purity than the average, while the low-profit margin does the opposite. However, Brazil’s iron ore exports fell sharply between January and May due to a sharp drop in supply after heavy rains earlier in the year, as well as declining mining production due to the dam’s failure in 2019.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: