dri iron manufacturer in world

Iran is the largest of dri iron manufacturer in Asia. One of the important achievements of the country’s steel industry is the achievement of Iranian technology for making sponge iron as one of the main products of steel production.

What is yield in sponge iron?

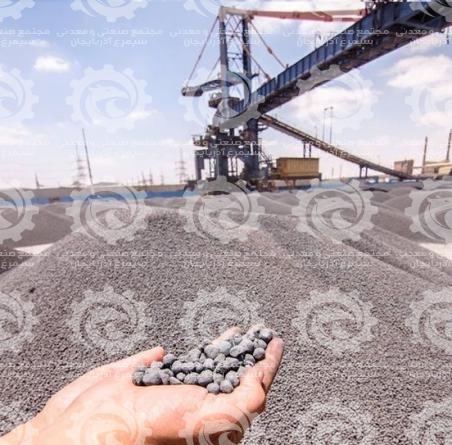

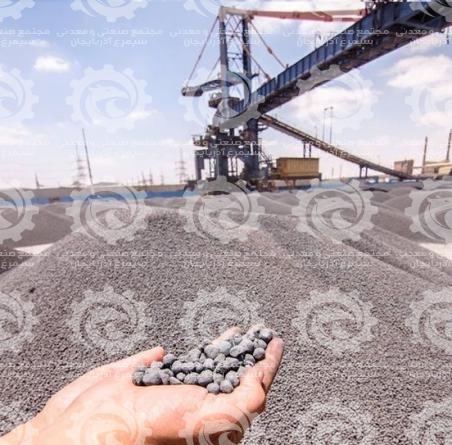

When oxygen is removed from iron ore immediately, sponge iron, also called porous pellets, is produced. The production of sponge iron takes place during the direct reduction of iron or Direct Reduced Iron without melting iron ore. The product of sponge iron, which is in the form of small balls, has a porous appearance and that is why it is called a sponge.

When oxygen is removed from iron ore immediately, sponge iron, also called porous pellets, is produced. The production of sponge iron takes place during the direct reduction of iron or Direct Reduced Iron without melting iron ore. The product of sponge iron, which is in the form of small balls, has a porous appearance and that is why it is called a sponge.

After melting, sponge iron is converted into three products: ingots, slabs, and rebars during the casting process, which are sent to factories for various uses, where they become other more widely used products. Pellets are high in iron and can be a good substitute for scrap iron. The remarkable thing about pellets is that it refers to sponge iron and is equivalent to it.

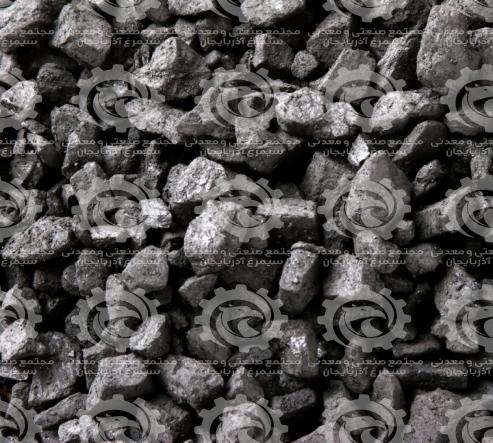

Iron ore is generally regenerated by natural gas and coal and leads to the production of sponge iron. The process of reducing iron ore with natural gas is done in three methods, Midrex, HYL and Purofer, of which, Midrex is the most widely used. Also, the process of reducing iron ore and producing sponge iron with coal is done by Jindal DRC and SL / RN methods. sponge iron uses For the production of various types of beams and rebars. which has made it popular.

dri iron manufacturer near me

Iran is the second largest producer of sponge iron in the world. Sponge iron is one of the raw materials for steel production due to its high purity. This product is used as feed for electric and induction arc furnaces and is technically an important competitor for scrap metal. Because natural gas is used in the sponge iron production process, production is limited to countries with abundant natural gas reserves. The important thing about sponge iron producers is that most of these countries, in addition to sponge iron production units, also have steel production units. Therefore, the trade of this product is often a function of the surplus and deficit of supply of producers who are also considered consumers. To clarify this, it should be noted that in recent years, on average, only 9% of the sponge iron produced in the world has been subject to world trade. Therefore, the amount of trade in this product depends on the volume of sponge iron production per year and the amount of steel production in the countries that produce this product. direct reduced iron prices This is due to economic sanctions and the Corona virus, which has reduced its production.

Iran is the second largest producer of sponge iron in the world. Sponge iron is one of the raw materials for steel production due to its high purity. This product is used as feed for electric and induction arc furnaces and is technically an important competitor for scrap metal. Because natural gas is used in the sponge iron production process, production is limited to countries with abundant natural gas reserves. The important thing about sponge iron producers is that most of these countries, in addition to sponge iron production units, also have steel production units. Therefore, the trade of this product is often a function of the surplus and deficit of supply of producers who are also considered consumers. To clarify this, it should be noted that in recent years, on average, only 9% of the sponge iron produced in the world has been subject to world trade. Therefore, the amount of trade in this product depends on the volume of sponge iron production per year and the amount of steel production in the countries that produce this product. direct reduced iron prices This is due to economic sanctions and the Corona virus, which has reduced its production.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: