Direct reduced iron content wholesalers

Over the past three decades, a new technology called the direct reduced iron content Process has been designed and developed extensively to restore iron ore to iron metal using coke or natural gas coal. Economic issues and environmental impacts have provided the background and incentive to research and study this process.

Use of direct reduced iron content

For many years, the blast furnace has been one of the most important and efficient methods in the field of iron production, and now it supplies more than 90% of the world’s iron needs. Process of iron production by blast furnace in terms of production rate; It has high efficiency but requires quality raw materials. Iron in high furnaces is produced by coke combustion, and coke prices are rising due to declining coking coal resources. Also, the process of preparing the raw materials for this process, such as assembling, coking and sintering, imposes a high cost on the steel industry. what is reduced iron formula? direct reduced iron prices is different.

For many years, the blast furnace has been one of the most important and efficient methods in the field of iron production, and now it supplies more than 90% of the world’s iron needs. Process of iron production by blast furnace in terms of production rate; It has high efficiency but requires quality raw materials. Iron in high furnaces is produced by coke combustion, and coke prices are rising due to declining coking coal resources. Also, the process of preparing the raw materials for this process, such as assembling, coking and sintering, imposes a high cost on the steel industry. what is reduced iron formula? direct reduced iron prices is different.

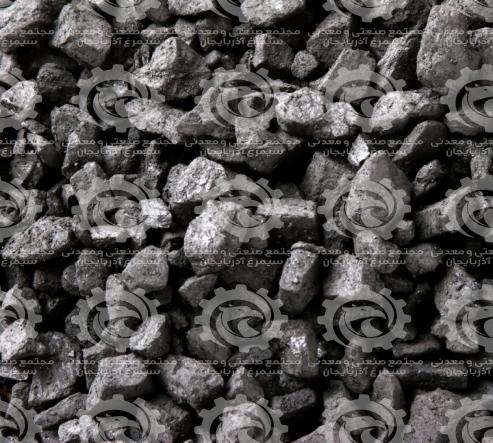

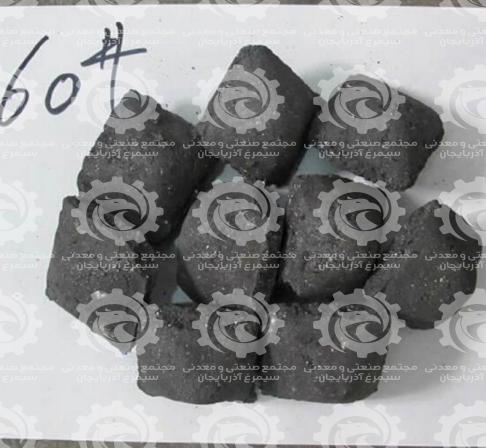

The process of direct reduced iron at temperatures below the melting point temperature removes the oxygen in the iron ore and makes its structure spongy porous. For this reason, this product is known as sponge iron and usually contains 92 to 96% pure iron. Sponge iron can be used, for example, as a raw material for the production of steel in an electric arc furnace.

Buy direct reduced iron content in bulk

As a result, it can be said that the blast furnace will have an uncertain future in the steel industry due to economic and environmental problems caused by the use of coke and sintering. Therefore, due to the huge resources of coking coal in the world, the high costs of the preparation process and the growing importance of environmental issues, the tendency towards new and alternative methods in this field is increasing day by day. One of these methods is the production of iron by direct reduction process. In such processes, a number of preparation steps are eliminated and as a result the costs and contamination associated with the whole process are significantly reduced.

As a result, it can be said that the blast furnace will have an uncertain future in the steel industry due to economic and environmental problems caused by the use of coke and sintering. Therefore, due to the huge resources of coking coal in the world, the high costs of the preparation process and the growing importance of environmental issues, the tendency towards new and alternative methods in this field is increasing day by day. One of these methods is the production of iron by direct reduction process. In such processes, a number of preparation steps are eliminated and as a result the costs and contamination associated with the whole process are significantly reduced.

Direct regeneration process is one of the new methods for iron production in which without the use of coking process or even in some cases without lumps; Iron is produced. The direct reduction of iron oxides by carbon has been extensively studied in recent decades. The costs of investing, setting up and maintaining a direct recovery process are much lower than other existing methods and can be used in small steel-making units with good economic justification. It is also a great option for many developing countries that are short of coal resources and face quality.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: