Direct iron reduction market growth rate

The price of Direct iron reduction for a higher grade is definitely more than a lump with a lower percentage of iron. Iron lump grade is often in the range of 54 to 62%. The higher the number of this quantity, the higher the percentage of iron and therefore its more valuable. The type of iron oxide (meaning the type of mineral) is also effective in determining the value and price of iron lumps. As you can see, the details and analysis of the product along with the price need to be mentioned when presenting the Direct Iron reduction price. The Direct iron reduction criterion you are requesting is a matter that the seller will ask before announcing the price and will determine and announce the price accordingly.

What is direct reduction of iron ore?

Direct iron reduction is a high-grade source for the manufacture of iron and steel obtained from the recycling of natural or processed iron ores without reaching the melting point. In this method, iron ore pellets with a grade of 67% are regenerated and the result is direct iron reduction (porous pellets) with metallization (about 92 degrees).

Direct iron reduction is a high-grade source for the manufacture of iron and steel obtained from the recycling of natural or processed iron ores without reaching the melting point. In this method, iron ore pellets with a grade of 67% are regenerated and the result is direct iron reduction (porous pellets) with metallization (about 92 degrees).

The product of the reduction unit is transferred to the steel section for direct charging of the furnace without passing the cooling part in the furnace and with a temperature of about 600 ° C by the special material transfer system.

Direct iron reduction After melting and reduction in steelmaking, in the casting process, it becomes the required products and is used in three forms: slab (billet), billet (ingot) and rebar. Today, about 5% of the world’s steel is produced from sponge iron (DRI), and this trend is increasing.

The application of Direct iron reduction in induction furnaces is one of its most important applications. It can be said that the use of sponge iron in induction furnaces is able to replace scrap by about 50%. But its application in induction furnace requires technical knowledge and experience. The use of sponge iron is also a major development in the continuous casting of the steel industry. The reduced iron formula is determined by experts.

Market growth rate of direct iron reduction

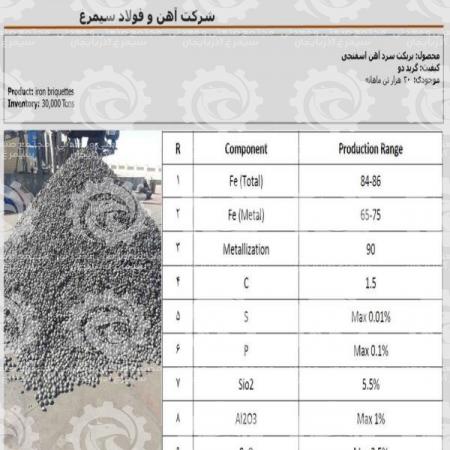

This type of product is sold in the country by various and reputable companies. Iron 20 system has also provided the possibility of buying and selling sponge iron, which you can simply refer to the purchase or sale advertisement section to view items related to sponge iron. Compressed direct iron, called briquette, has fewer transportation problems and is easier to store. In addition, the briquette has a higher resistance to abrasion and rust and is less likely to cause porosity (surface separation). direct reduced iron prices are determined according to its quality.

This type of product is sold in the country by various and reputable companies. Iron 20 system has also provided the possibility of buying and selling sponge iron, which you can simply refer to the purchase or sale advertisement section to view items related to sponge iron. Compressed direct iron, called briquette, has fewer transportation problems and is easier to store. In addition, the briquette has a higher resistance to abrasion and rust and is less likely to cause porosity (surface separation). direct reduced iron prices are determined according to its quality.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: