Dri sludge main products

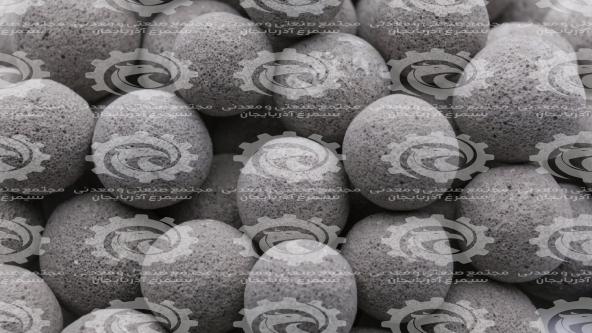

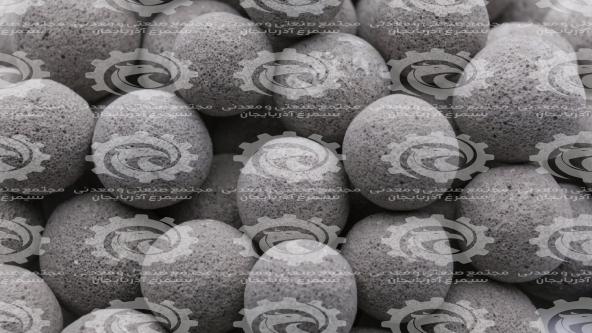

The high grade of sponge iron has made it a good source of iron and steel. As mentioned, the sponge extract is obtained from recycling natural or processed iron ore that has not reached the melting point. Iron ore reduction in Iran is DRI sludge done using Midrex technology.

Experimental analysis of dri sludge

In this technology, iron ore pellets are immediately regenerated with broken gases. In this method, iron ore pellets with a grade of 67% are regenerated and sponge iron (porous Dust and Sludge Recycling) is produced by Fe metallization (about 92 degrees). The product produced in the regeneration unit does not undergo the cooling part in the furnace and is transferred to the steelmaking section for direct charging of the furnace by the special material transfer system with a temperature of about 600 C. They also say. As mentioned, the sponge extract is obtained from recycling natural or processed iron ore that has not reached the melting point. Iron ore reduction in Iran is DRI sludge done using Midrex technology.

In this technology, iron ore pellets are immediately regenerated with broken gases. In this method, iron ore pellets with a grade of 67% are regenerated and sponge iron (porous Dust and Sludge Recycling) is produced by Fe metallization (about 92 degrees). The product produced in the regeneration unit does not undergo the cooling part in the furnace and is transferred to the steelmaking section for direct charging of the furnace by the special material transfer system with a temperature of about 600 C. They also say. As mentioned, the sponge extract is obtained from recycling natural or processed iron ore that has not reached the melting point. Iron ore reduction in Iran is DRI sludge done using Midrex technology.

Buy various products of dri sludge

Sponge iron is a good alternative to iron scrap, so it is possible to use this material to provide a high percentage of raw materials to provide the smelting required by steelmaking units instead of using scrap. One of the most important applications of sponge iron in induction furnaces. Induction furnaces may replace scrap iron with about 50 percent sponge iron. Of course, keep in mind that technical knowledge and experience are required to use it in an induction furnace. In addition, sponge iron has revolutionized the continuous casting of the steel industry.

Sponge iron is a good alternative to iron scrap, so it is possible to use this material to provide a high percentage of raw materials to provide the smelting required by steelmaking units instead of using scrap. One of the most important applications of sponge iron in induction furnaces. Induction furnaces may replace scrap iron with about 50 percent sponge iron. Of course, keep in mind that technical knowledge and experience are required to use it in an induction furnace. In addition, sponge iron has revolutionized the continuous casting of the steel industry.

After melting and resuscitation in steelmaking, sponge iron is used in the casting process in three forms: slab, slab, and rebar. About 5% of the world’s steel is now made from sponge iron (DRI), and the trend is growing. Pellet is a combination of iron produced from concentrated iron ore (Method for Producing Briquettes from Pellet Fines). The amount of pellets used in DRI production per ton of crop is about 1.45 tons. It is worth noting that the choice of direct iron ore recovery method depends on the location of the manufacturer and the available resources. For example, in Iran, considering the rich sources of gas, the choice of gas sources is a more logical choice and gas is used as a reducing agent. As you know, the use of coal resources for recycling also leads to air pollution problems, and its mines are not readily available. But now the world’s largest producer of sponge iron in India, which is reviving iron ore by relying on coal resources.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: