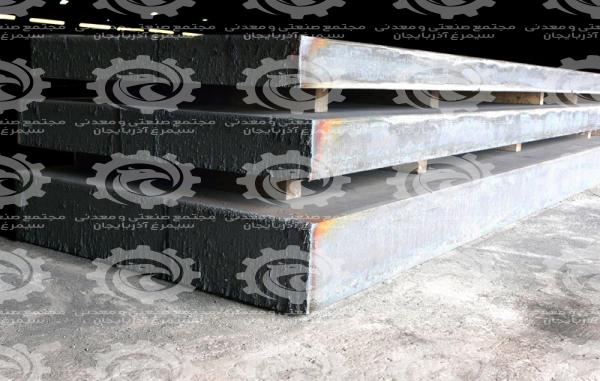

Superior steel slabs domestic market

The rollers are cooled by a water cooling system and flow and pressure control depending on the type of rolling process. Due to the high temperature of the sheet, a thin oxide layer is formed on the surface and a secondary descaler (built-in descaler) is used to remove this oxide layer, which is made by spraying water at 225 pressure. rod on their surface. For more information on the Superior steel slabs domestic market, visit our site.

Unique Characteristics of Superior steel slabs

X Ray device: During on-line rolling, this equipment takes the thickness of the sheet longitudinally and continuously and sends its report to adjust the HAGC and control the thickness in the next rolling pass. This equipment is located after the stand.

X Ray device: During on-line rolling, this equipment takes the thickness of the sheet longitudinally and continuously and sends its report to adjust the HAGC and control the thickness in the next rolling pass. This equipment is located after the stand.

Gamma ray machine: This equipment is placed behind the X-Ray machine, which measures length and width and thickness at three points in the transverse profile at the last pass and sends its report to Level 2 to check and correct the rolling process. This equipment is very advanced and unique in the country.

Equip Accelerate cooling system This system is placed behind the stand, the function of this system is thermomechanical rolling (change in microstructure, granulation and change in mechanical properties), which should reduce the temperature of the hot plate to the desired temperature.

This system includes:

- 1- The main cooling pipes (Top Heads) are each equipped with the required number of nozzles to spray water on the sheet surface, the number of these pipes is 12, and water is sprayed with 0.8Bar pressure. These nozzles made on the plate surface are U-shaped.

- 2- Air pipes are installed at the beginning and end of this pipe system to dry the remaining water layer.

- Hot Plate Balancer The hot surge arrester is located after the stand and the ACC system.

The number of rollers in the hot surge arrester is 9, 4 in the upper cassette and 5 in the lower cassette, and their cooling is done in the form of spin. In order to eliminate the wave in different areas along the plate of this device, the position is changed in the Skew, Tilt and Tilt positions and finally the wave is made by applying one of these positions. Cooling substrates are disc type. The hot plate enters this area after being marked with the Hot Plate Marker. Beds 1 and 2 each consist of three parts, including a stuffing machine and rotating discs to transfer the sheet and a mattress evacuation machine.

The area of each of these cooling beds is 1840 mm, respectively 46m and 40m in length and width. Each platform consists of two parts. Depending on the length of the page, Sec 1 or Sec 2 or both can be selected. The exit temperature of the layers from the substrates is below 120 ° C. After the beds, boards with a maximum thickness of 50 mm are directed to the control table. The slow cooling zone is used for thermomechanical rolling or steels that need to reduce the amount of H2. So much so that the bed sheet, whose temperature is about 500 degrees, comes out of the cooling bed and is stacked in this area to cool it slowly.

Device Rotation equipment is used in the examination table. In this way, both surfaces of the sheet can be inspected. All processes in the area of cooling beds are controlled and directed by cameras and instrumentation equipment. For more information on steel slabs cargo visit our site.

Domestic market of Superior steel slabs

Domestic market of Superior steel slabs has grown well and this product is also exported to other Asian and European countries. Therefore, dear customers can refer to our site about steel slabs used and buy this product.

Domestic market of Superior steel slabs has grown well and this product is also exported to other Asian and European countries. Therefore, dear customers can refer to our site about steel slabs used and buy this product.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: