Superior iron pellets market value

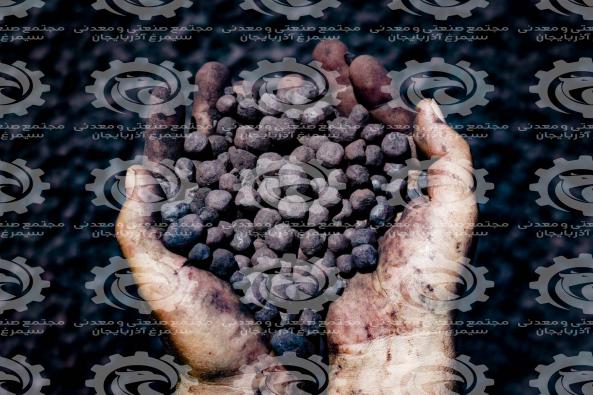

Pellets are made from fine iron ore and other additives, which are first raw and then cooked and hardened and used for reduction by the traditional iron production method in the blast furnace or by various direct reduction methods. The advantage of using different concentrates of input concentrate High quality product due to the choice of Alice Chalmers technology Design and implementation of parts of the concentrate production plant, including mills, thickeners and press filters. For more information about Superior iron pellets market value, visit our site.

Is iron pellets in high demand?

. Since the concentrate, which is a product of the ore production facility, is in the form of granular iron ore that cannot be physically used in this way, these fine particles unevenly reduce the gas permeability at the blast furnace load and the operation of the blast furnace.

. Since the concentrate, which is a product of the ore production facility, is in the form of granular iron ore that cannot be physically used in this way, these fine particles unevenly reduce the gas permeability at the blast furnace load and the operation of the blast furnace.

They also cause problems in the direct reduction plant, so they convert iron pellets, which are considered as intermediates from mines to furnaces for iron and steel production, into pellets. Since pellets are raw materials, they must have the desired mechanical, chemical and thermal properties in reduction furnaces. Pellets are spheres made from natural iron concentrates and ores that differ in mineralogical and chemical composition. In fact, the purpose of the pelletizing unit is to convert the iron concentrate into geometry and porous iron pellets.

Pellets have the following features: Even distribution of sizes from 9 to 16 mm predominantly High and uniform porosity 25 to 30% Uniform mineral composition in the form of hematite or regenerative hematite compounds High and homogeneous mechanical strength Abrasion resistance Sufficient mechanical strength even against heat stress in regenerative environments Low adhesion Pellets are a raw material for crude iron production. Small pellets made from iron ore and other hard or cooked additives. The pellets used in the direct reduction method have a higher grade of iron and less impurities than blast furnace pellets.

Pellets used in the blast furnace must have a larger size and a higher strength, which depends on the size of the blast furnace. The degree of regeneration also depends on the degree of porosity, contact surface and solid gas contact. To produce this product, crushed and milled iron ores with grains between zero and one hundred microns are supplied worldwide as pellet feed. These raw materials, if supplemented in a short time, for direct reduction units such as steel complexes. Ahvaz and Mobarakeh, which are equipped with pelletizing equipment, are considered suitable loads. In some direct reduction processes, raw and hardened pellets are also used.For more information on types of iron ore pellets visit our site.

Market value of Superior iron pellets

Market value of Superior iron pellets is very good and has good sales growth so that it is exported to other countries and good trade can be done with this product. Therefore, you can visit our site for more information about iron ore pellet specifications.

Market value of Superior iron pellets is very good and has good sales growth so that it is exported to other countries and good trade can be done with this product. Therefore, you can visit our site for more information about iron ore pellet specifications.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: