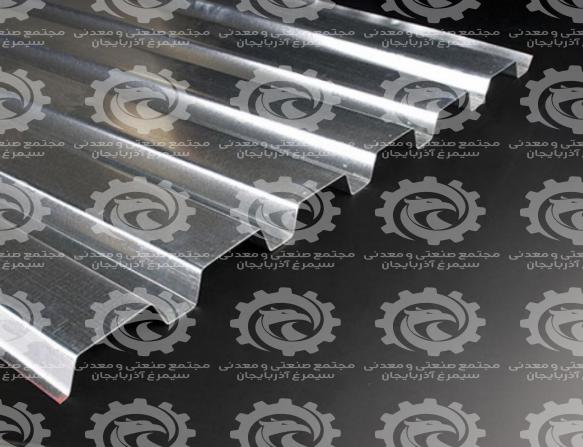

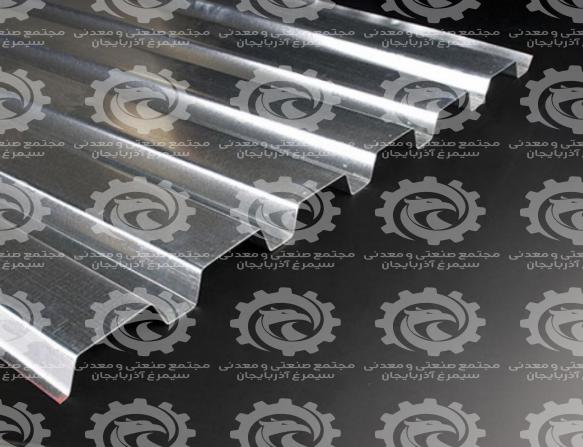

Superior galvanized sheet Wholesale production

The iron in which the metal is impregnated is called galvanized sheet and this process is called galvanizing. The amount of zinc coating on the sheet varies between 100 and 350 grams per square meter, depending on the metal mass on them. . Galvanized sheet is produced in two forms as roll form and fabric. Galvanized coil sheet is available in various thicknesses from 0.18 mm to 6 mm in two widths, 100 cm and 125 cm. In addition, galvanized fabric sheets of 2000 * 1000 mm and 2500 * 1250 mm are produced. The weight of each galvanized coil is about 5 to 7 tons, depending on its width and thickness. For more information about superior galvanized sheet wholesale production, visit our site.

How Superior galvanized sheet is made?

The first stage of the galvanizing process is the degreasing process in which the surface of the parts is cleaned of paint, oil, grease and other compounds, but other compounds that contaminate the surface and are not removed at this stage are washed in the next stage. (acid wash). Some paint and oils are not easily removed from surfaces and require sandblasting and sandblasting. The process of throwing sand and gravel with very high air pressure is called sand blasting. After degreasing, all surfaces are inspected to remove all paints, oils, greases and all kinds of cleaning components from the surfaces.

The first stage of the galvanizing process is the degreasing process in which the surface of the parts is cleaned of paint, oil, grease and other compounds, but other compounds that contaminate the surface and are not removed at this stage are washed in the next stage. (acid wash). Some paint and oils are not easily removed from surfaces and require sandblasting and sandblasting. The process of throwing sand and gravel with very high air pressure is called sand blasting. After degreasing, all surfaces are inspected to remove all paints, oils, greases and all kinds of cleaning components from the surfaces.

It should be noted that the hanging parts are hidden during the galvanizing process. For this purpose, a device that can move suspended parts during the preparation and dipping stages should be provided. Before starting the preparation process, it should be noted that any contamination such as paint, grease, oil, etc. must be removed from the surface of the parts. The placement and internal pores of the parts must be such that washing solutions and molten zinc can flow into all areas of the part. During the design, the components of the structures must be provided in such a way that there are no dead ends inaccessible to air, washing solutions (degreasers, acids and fluxes) and finally melt.

At this stage, the parts are immersed in a hydrochloric acid bath to remove paint, shell and other metal oxides. In order for the zinc melt to react completely with the steel, the surface of the steel must be completely removed from these contaminants. Deep and heavy rust may not be easily removed by acid washing, so other mechanics may be required. methods Used for cleaning the surface before washing with acid.

The zinc melt, a zinc alloy that forms a very strong bond with the steel surface, reacts with the steel surface thoroughly cleaned in previous stages to form an iron layer. Galvanized coating is formed within the first 2 to 3 minutes after entering the melt bath, depending on the thickness of the steel in each case. For more information about galvanized sheet metal visit our site.

Wholesale production of Superior galvanized sheet

Wholesale production of Superior galvanized sheet is possible by the production unit of our company and we distribute this product to the market at a reasonable price. Therefore, you can visit our site for more information about galvanized sheet price.

Wholesale production of Superior galvanized sheet is possible by the production unit of our company and we distribute this product to the market at a reasonable price. Therefore, you can visit our site for more information about galvanized sheet price.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: