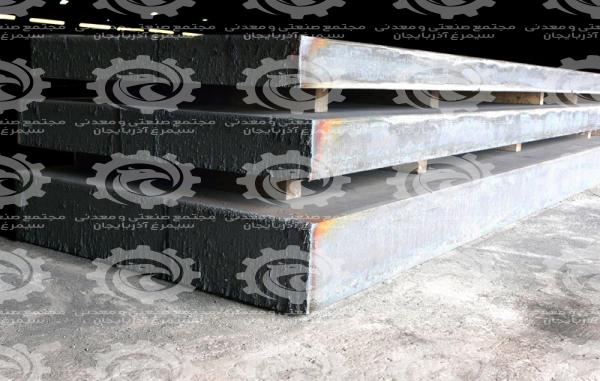

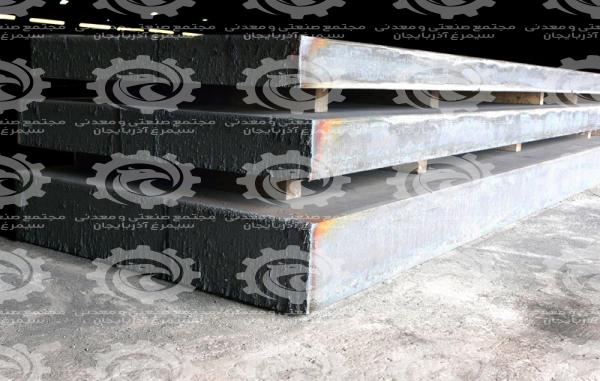

Superb steel slabs market share in 2021

The raw materials of the production line enter the slab area with trucks or train wagons. This area has an area of 7650 square meters (255 x 430) and is equipped with 3 magnetic overhead cranes, each of which can be hooked. The capacity of each crane (for the transportation of hot return plates from the furnace) is 800KN, or 80 tons. For more information on Superb steel slabs market share in 2021, visit our site.

Which steel slab is best for column?

Reheating Furnace preheating furnaces are located after the floor area. These furnaces are walking type (Walking beam reheating furnace) and their interior dimensions are 34.7m length, 10m width and 4.5m height. The boards are placed on the loading table with the cranes in the floor area and move in an automatic and special order on the roller table, which will be sent to the furnace to be charged after weighing.

Reheating Furnace preheating furnaces are located after the floor area. These furnaces are walking type (Walking beam reheating furnace) and their interior dimensions are 34.7m length, 10m width and 4.5m height. The boards are placed on the loading table with the cranes in the floor area and move in an automatic and special order on the roller table, which will be sent to the furnace to be charged after weighing.

The steps of loading and unloading the sheets by machine are done automatically. The fuel for these furnaces is natural gas. The preheated air is heated by the fans using a recuperator system and sent to this path to supply fuel to the burners. Analysis of exhaust gases from the furnace is measured with installed online analyzers. In addition, the transportation of materials inside the furnace is controlled by cameras made with fixed and movable columns and beams. The cooling of the columns and beams in the furnace is done with closed circuit water circulation.

The loading of the slab, the heating and unloading of the slab from the furnace, and all stages of the slab tracking are controlled by the programs found in Level 1 and Level 2 automation. Due to the dimensions of the slab, the heating time of each slab takes approximately 3.5 hours. Due to the oxidation of iron at high temperatures, an oxide shell layer is formed on the plate after unloading from the furnace, for this purpose a scaling device is placed after the furnace. In this part, spraying water on the plate (steel ingot) with a pressure of 225 bars causes the surface oxide layers to peel and separate from the material.

In this machine, the distance between the ingot surface and the water spray nozzles can be controlled according to the thickness of the sheet. After stripping, the plate enters the climbing rack. The rotating rack has 4 rollers, 2 of which are called Work Rolls and the other 2 rollers Back Up Rolls. It can be raised to the desired sheet width. For more information about steel slabs for sale visit our site.

Market share of Superb steel slabs

Market share of Superb steel slabs is growing well and has made the trade of this product grow well every day. Therefore, you can visit our site for more information about prime steel slabs.

Market share of Superb steel slabs is growing well and has made the trade of this product grow well every day. Therefore, you can visit our site for more information about prime steel slabs.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: