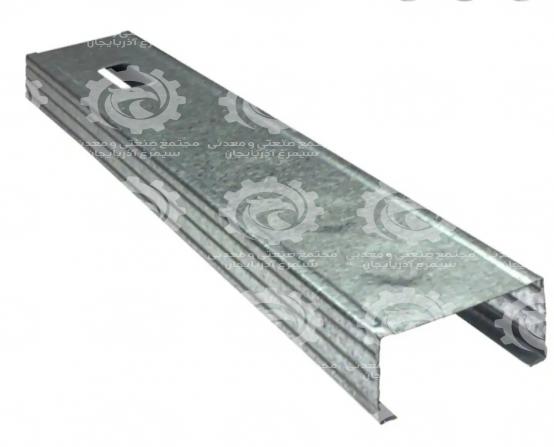

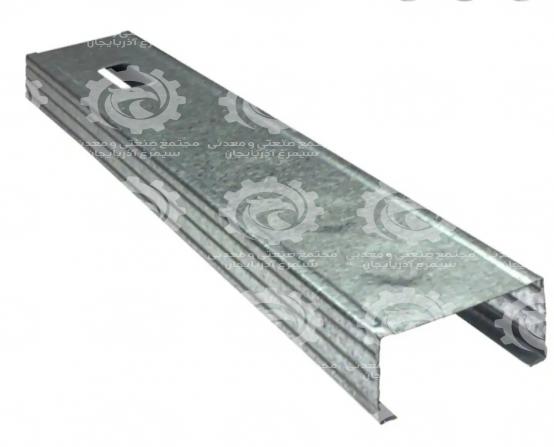

Steel stud Wholesale Market

The steel deck stud is responsible for connecting the rest of the deck and components based on the tension and transmission force between concrete and steel. For this reason, it is also known as the cut base. The steel deck stud is welded directly or from galvanized sheet to the beam wing. In fact, it can be said that the post acts as an interface between galvanized sheet and concrete. For more information on the Steel Stud Wholesale Market, visit our site.

Can steel studs support weight?

Studs are made of alloyed steel and carbon during the cold forging process, each with various applications in construction, different diameters and heights in different cross-sections. Basically, cutters are made with a diameter of about 2 cm and a minimum height of about 40 mm, the height varies according to the height of the steel sheet. Nails play a very important role in joint construction, so they must have a very high quality and strength, so if they are of poor quality, they can damage the entire structure.

Studs are made of alloyed steel and carbon during the cold forging process, each with various applications in construction, different diameters and heights in different cross-sections. Basically, cutters are made with a diameter of about 2 cm and a minimum height of about 40 mm, the height varies according to the height of the steel sheet. Nails play a very important role in joint construction, so they must have a very high quality and strength, so if they are of poor quality, they can damage the entire structure.

The welding process involves the formation of an initial electric arc and eventually a main arc between the tip of the stud and the workpiece. An electric arc is created first, and both the stud and the workpiece begin to melt and eventually merge. In the next step, the end of the material enters the melting stage. After the welding step, dip the stud into the molten pool to complete the welding step. Welding is done with a special stud welding machine and the input ampere level must be set for each size. A diesel generator with a power of at least 200 kw is required to power the device.

In the absence of a diesel generator, manual welding of the studs is not prevented (this method is relatively slow). The distances of the posts along the support beam should not exceed at least 8 times the slab thickness or 80 cm. Its maximum diameter should not be less than 20 mm and its minimum height from the top edge of the congress be less than 40 mm. Use high strength alloy steel and cold forged type studs. Before use, it should be inspected randomly for visual defects such as studs, cracks and porosity. Before welding, studs must be completely clean and free from any rust, oil and moisture. Use 8 feather and preferably 12 feather ceramic pieces to fully protect the resource.

The higher the number of blades, the less diffusion of the melt pool and better protection against welding during application. The welding ceramic protection ring must be completely dry. If there is moisture, it can be used after it dries completely. The work surface must be completely clean. The presence of a thick layer of paint on the beams causes defects such as porosity and reduces the welding quality of the studs. The skill of the operator is very effective in welding quality. It is recommended to take and check a limited number of samples before making the entire roof strut. The welding gun should be held upright in the weld place until the end of the welding process and the molten pool has hardened. After making the studs, check the accuracy of the welding process using the bend test. For more information on steel stud framing prices visit our site.

Wholesale Market of Steel stud

Wholesale Market of Steel stud is growing and good, and this product, due to its quality and price, many customers are requesting to buy this product. So you can visit our site for more information about steel studs Bunnings.

Wholesale Market of Steel stud is growing and good, and this product, due to its quality and price, many customers are requesting to buy this product. So you can visit our site for more information about steel studs Bunnings.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: