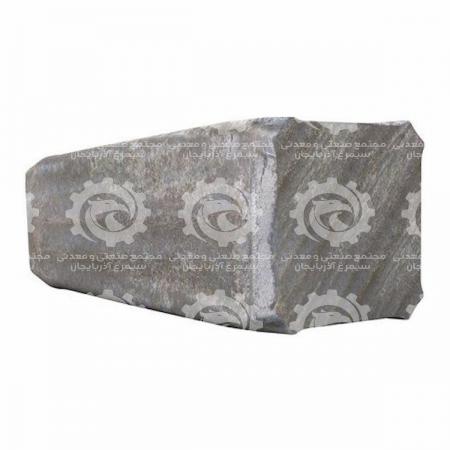

Stainless steel ingots Price Fluctuation

The use of stainless steel coatings has also been expanded to meet stubborn hygiene and cleaning requirements. The developed production process has resulted in greater stability of the surface coverage both along a sheet and from batch to batch. Products can now only withstand a few subsequent fluctuations. Please visit our website for more information on stainless steel ingots.

Positive features of stainless steel ingots

Stainless steel tubes are traditionally manufactured by inert tungsten inert gas welding, while with the advent of the reliable and powerful laser power source, the laser beam welding process (LBW) has quickly transitioned to the manufacture of longitudinally welded stainless steel tubes. The amount of energy gained at the focal point of the laser beam is very high and can create deep welds in thin sections of stainless steel with minimal distortion of the components. This process initially used expensive equipment and mass production.

Stainless steel tubes are traditionally manufactured by inert tungsten inert gas welding, while with the advent of the reliable and powerful laser power source, the laser beam welding process (LBW) has quickly transitioned to the manufacture of longitudinally welded stainless steel tubes. The amount of energy gained at the focal point of the laser beam is very high and can create deep welds in thin sections of stainless steel with minimal distortion of the components. This process initially used expensive equipment and mass production.

Although smaller devices have become more widespread, the use of laser welding is more widespread. In addition to hollow profiles, I-shaped profiles, angles and other shapes are also available. In recent years, there has been increasing use of stainless steel laser cutting, which uses a focused laser beam to melt matter in a localized area. A coaxial jet of gas is used to bring the molten material back from the cutting edge to create a clean and continuous cutting edge which is achieved by moving the laser beam or workpiece under the control of a CNC machine. There are no injection molding costs, prototyping is carried out quickly and quickly bypassed.

Advances in precision, square edge, and inlet heat control are causing other mold making techniques, such as plasma cutting and air-gas cutting, to switch places in laser cutting. The performance of stainless steel in constructions differs from that of carbon steels because stainless steel has no specific yield strength and an early exit from linear elastic behavior when elongated shows strong stiffness. There is also a big difference in the stress-strain diagram with carbon steels. This means that it influences the buckling behavior of the components and the deflection of the beams. Designers need guidance on how to choose the right grade and use stainless steel correctly in contact with other metals (e.g., carbon steel, reinforced concrete, masonry, wood, and aluminum) to avoid corrosion due to differences in materials.

Bonding methods also require special guidelines, especially if the welding is to maintain surface coverage and corrosion resistance. Before updating the design standards for stainless steel structures, designers are asked to follow their design process and not think of stainless steel and use it as the second preferred material that has been proven to be successful and that serves as a design guide.

You were asked to work according to the first principles, working from an unknown and expensive material with unusual mechanical properties. This was an unfavorable situation, in the best case a waste of designer time, in the worst case it led to a misunderstanding of the construction work, to abuse or non-repair or to mistakes. For more information on the please steel ingots manufacturing process visit our website.

Price changes of stainless steel ingots

Price changes of stainless steel ingots are due to fluctuations in the foreign exchange market that have affected this product and caused prices to change, so you can visit our site for more information about stainless steel ingot price.

Price changes of stainless steel ingots are due to fluctuations in the foreign exchange market that have affected this product and caused prices to change, so you can visit our site for more information about stainless steel ingot price.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: