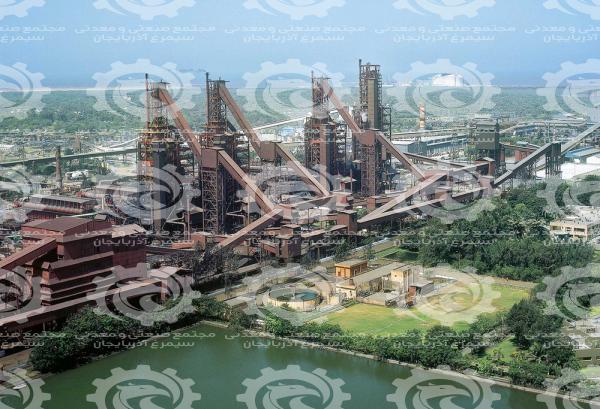

Sponge iron Manufacturing process

Sponge iron is a metal product that is produced by a direct reduction of iron ore in solid-state. Sponge iron is a good alternative to waste and is mainly used in the manufacture of steel via secondary routes. The process of making sponge iron occurs by removing oxygen from the iron ore. The quality of sponge iron is mainly determined by the percentage of metallization (removal of oxygen). This parameter is equal to the ratio of metal iron to total iron in the product. Sponge iron itself is not used but can be processed to produce molten iron. The dangers of sponge iron include environmental pollution.

The common use of sponge iron

The importance of iron and steel in global development is such that it can be said that iron is the foundation of today’s civilization. Frequency, low price, recyclability, high strength, as well as alloying ability, have created a variety of features in its use. The scope of this diversity extends from needle and pin production to giant slaughterhouses and skyscrapers. Because the steel industry, including industry, is highly capitalized and in need of technology, it is called the parent industry because of its great impact on the industrial development of sponge iron grades. According to international standards, the production of one million tons of steel will directly create employment for about a thousand people. On average, for every person working directly in the steel industry, 3.5 people will work in related industries.

The importance of iron and steel in global development is such that it can be said that iron is the foundation of today’s civilization. Frequency, low price, recyclability, high strength, as well as alloying ability, have created a variety of features in its use. The scope of this diversity extends from needle and pin production to giant slaughterhouses and skyscrapers. Because the steel industry, including industry, is highly capitalized and in need of technology, it is called the parent industry because of its great impact on the industrial development of sponge iron grades. According to international standards, the production of one million tons of steel will directly create employment for about a thousand people. On average, for every person working directly in the steel industry, 3.5 people will work in related industries.

Explain manufacturing process of sponge iron

Sponge iron production is very sensitive to the characteristics of raw materials. Therefore, it is very important to study the chemical and physical properties of raw materials separately in the composition. Raw materials for the production of sponge iron include iron ore, non-coal, and dolomite. For direct iron ore regeneration, the main kiln used is the rotary kiln. The spherical or spongy spherical parts, which are produced by the direct reduction of iron ore (Direction Reduce Iron) and the removal of oxygen, are called sponge iron. Sponge iron has a high grade of iron (84 to 95%) and one of the reasons for its prevalence is the shortage and increase in the price of iron waste and environmental problems. The use of sponge iron in induction furnaces is considered as one of its most important applications, so that instead of full use of iron wastes, a high percentage (50%) of raw materials to provide the required smelting of steel units, Sponge iron is supplied.

Sponge iron production is very sensitive to the characteristics of raw materials. Therefore, it is very important to study the chemical and physical properties of raw materials separately in the composition. Raw materials for the production of sponge iron include iron ore, non-coal, and dolomite. For direct iron ore regeneration, the main kiln used is the rotary kiln. The spherical or spongy spherical parts, which are produced by the direct reduction of iron ore (Direction Reduce Iron) and the removal of oxygen, are called sponge iron. Sponge iron has a high grade of iron (84 to 95%) and one of the reasons for its prevalence is the shortage and increase in the price of iron waste and environmental problems. The use of sponge iron in induction furnaces is considered as one of its most important applications, so that instead of full use of iron wastes, a high percentage (50%) of raw materials to provide the required smelting of steel units, Sponge iron is supplied.

The direct iron ore recovery (sponge iron price) method is performed according to the location of the manufacturer and the available resources through gas or coal resources. In Iran, for example, gas is used as a reducing agent, despite its rich gas resources. Although coal resources are not a good source of recovery due to air pollution problems and lack of easy access to mines, India is currently the world’s largest producer of sponge iron. The reducing agent is used. Types of gas reduction methods include Midrex, Purofer, and HYL methods, and coal reduction methods include SL methods. He mentioned RL (SL / RN), Jindal, and DRC. Midrex method is one of the most useful methods of resuscitation in Iran and the world.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: