Sponge iron Local Suppliers

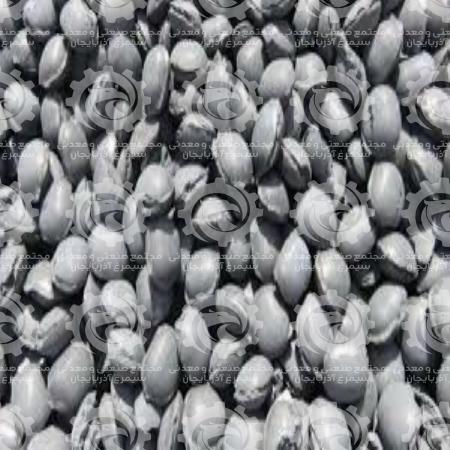

Sponge is a product of direct reduction operations produced in two ways, based on iron, gas or coal. The sponge, produced by the tunnel kiln method, is based on charcoal and is thought to have been replaced by crumbs for melting in electric kilns by artisans due to its high metal content. For more information on sponge irons, visit our website.

Unique Characteristics of sponge iron

Different parameters are more effective in sponge ferrous metal, including the shelf life of the reducing vessels in different parts of the furnace, the material of the reducing vessel, the type of thermal coal used as a reducing agent for coal granulation. research, the optimal conditions of each of these parameters are expressed relatively after various experimental tests. For the production of spherical graphite iron with low manganese content, low manganese sponge iron produced by the tunnel kiln method was used to achieve chemical analysis of ingots.

Different parameters are more effective in sponge ferrous metal, including the shelf life of the reducing vessels in different parts of the furnace, the material of the reducing vessel, the type of thermal coal used as a reducing agent for coal granulation. research, the optimal conditions of each of these parameters are expressed relatively after various experimental tests. For the production of spherical graphite iron with low manganese content, low manganese sponge iron produced by the tunnel kiln method was used to achieve chemical analysis of ingots.

To compare the melting efficiency, crumb iron was also loaded with Midrex sponge iron. The results of various experiments show that due to the high metal content of the tunnel kiln sponge iron compared to Midrex sponge iron, the melting efficiency is very close to the melting efficiency of the crumbs, and the melting was in this state. Most small and large steel mills in Iran use sponge iron instead of scrap iron. High-grade raw materials for smelting steel mills are always sponge iron instead of scrap iron. One of the most important applications of sponge iron is in induction furnaces, which use about 50% instead of scrap iron.

The use and application of sponge iron in induction furnaces requires sufficient knowledge and experience that does not reduce the efficiency of the furnace and does not react negatively, but the necessary knowledge and information must be used to make a big difference in casting and steel.

Direct resuscitation methods Direct reduction of iron ore is carried out in two ways: direct reduction by gas sources, direct reduction by coal Recovery directly through gas sources Choosing the right method for direct recovery depends on the location of the plant and the available source. The direct reduction method through gas reserves is mostly used due to Iran’s rich gas reserves and the use of gas as a reducing agent. For more information sponge iron in bulk visit our website.

Focal suppliers of sponge iron

Our collection is one of the Focal suppliers of sponge iron and we export this product to other countries, whose affordable price has a great impact on economic growth that you can For more information about sponge iron export, visit our site.

Our collection is one of the Focal suppliers of sponge iron and we export this product to other countries, whose affordable price has a great impact on economic growth that you can For more information about sponge iron export, visit our site.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: