Iron ore pellets Price Fluctuation

What is the price of iron ore pellets in Iran? Maybe this is your question too! The fact is that the measurement and price of iron pellets in Iran and other countries is determined through the daily price chart of the Metal Bulletin and the Pellets index. Hence, many traders use the Pellets index to buy and sell iron pellets.

How are iron ore pellets made?

It is usually melted to form iron ore or to produce crude iron (metal steel). This is probably because iron is one of the most important metals in developed and developing countries. Cast iron (iron less than 3% coal and very hard), iron (other than iron as iron), and porcelain iron sheet iron. Pure iron is very high in magnetite and melts at 1528 ° C. Magnesium is used to remove impurities in coal washing and may be recovered and reused. The amount of iron ore reserves in Iran is about 4.5 billion tons. It is estimated that 2.5 billion tons of iron ore is definite

It is usually melted to form iron ore or to produce crude iron (metal steel). This is probably because iron is one of the most important metals in developed and developing countries. Cast iron (iron less than 3% coal and very hard), iron (other than iron as iron), and porcelain iron sheet iron. Pure iron is very high in magnetite and melts at 1528 ° C. Magnesium is used to remove impurities in coal washing and may be recovered and reused. The amount of iron ore reserves in Iran is about 4.5 billion tons. It is estimated that 2.5 billion tons of iron ore is definite

The iron minerals that make up iron ore deposits are more common than magnesium oxide (manite and homitatus) and are not active on other iron compounds. According to statistics, Iran’s iron ore production capacity last year was about 38 million tons, 17 million and 200 thousand tons were exported, 21 million tons were consumed domestically and 19.2 million tons of pellets were produced. This amount of iron ore has been extracted from 99 iron ore mines in the country. Out of 112 mines in the country, there are 105 mines for the private sector and 7 mines owned by the government. The actual reserves of active mines are more than 2 billion and 355 million tons, which are mainly located in the provinces of Isfahan, Zanjan, Semnan, Fars, Kerman, Markazi, Hormozgan, Yazd and Kurdistan. Most of the world’s major sources of this mineral are iron-rich sedimentary rocks, the BIFs, which are almost exclusively from the Precambrian period (more than 600 million years ago). This makeup is available on every continent.

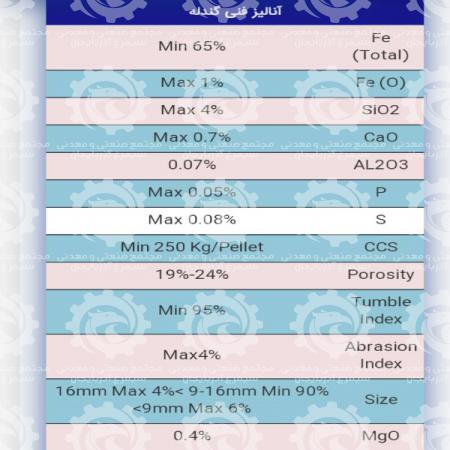

In many cases they are mined as iron ore. This mineral has different types and has different appearance shapes. The main iron ores are hematite and magnetite. Iron ores are mined from these ores. There are mines of this ore in the heart of the earth in which this ore has been formed during geological periods and how each iron ore mine is formed is different from each other. In the continuation of this article, we will discuss how this mineral was formed. iron ore pellet specifications are determined according to its type.

Price changes of iron ore pellets

The price of iron ore pellets is not fixed and varies according to market fluctuations, supply and demand, economic conditions of the country, etc. Iron ore pellets are made from soft iron ore and are used in reduction units and smelting units. Pellets are made of soft iron ore in the form of pellets, which are first raw and then hardened and cooked. In blast furnaces, it is regenerated in various ways and used to produce iron. Pellets are essentially the raw material for making iron, which must be properly regenerated by blast furnaces. In this method, raw pellets are pumped through 90% iron ore with a solution such as water and the result is pellet pellets. In order to improve the quality of iron ore pellets, materials such as calcium hydroxide and some mechanical metallurgical properties are added to it. Up to this stage, the pellets are formed in raw form, which must be heated in an oxidizing atmosphere after being transferred to the device in order to harden. In the last stage of cooking and cooling, it should be done in such a way that the crack does not get in the iron pellet.iron ore pellets market is booming.

The price of iron ore pellets is not fixed and varies according to market fluctuations, supply and demand, economic conditions of the country, etc. Iron ore pellets are made from soft iron ore and are used in reduction units and smelting units. Pellets are made of soft iron ore in the form of pellets, which are first raw and then hardened and cooked. In blast furnaces, it is regenerated in various ways and used to produce iron. Pellets are essentially the raw material for making iron, which must be properly regenerated by blast furnaces. In this method, raw pellets are pumped through 90% iron ore with a solution such as water and the result is pellet pellets. In order to improve the quality of iron ore pellets, materials such as calcium hydroxide and some mechanical metallurgical properties are added to it. Up to this stage, the pellets are formed in raw form, which must be heated in an oxidizing atmosphere after being transferred to the device in order to harden. In the last stage of cooking and cooling, it should be done in such a way that the crack does not get in the iron pellet.iron ore pellets market is booming.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: