Iron ore of pakistan Production by Year

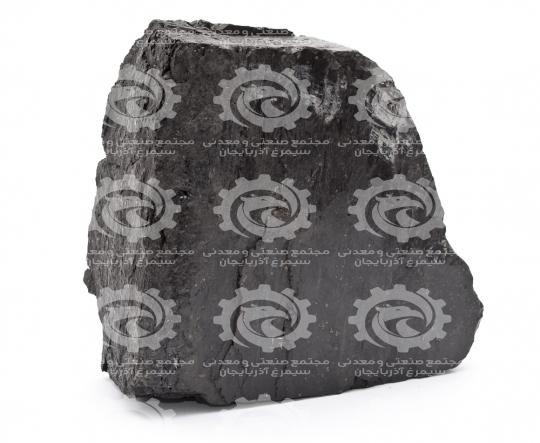

Iron ore is the pellet whose oxygen is removed following a direct (iron ore of pakistan) regeneration process without the need for iron ore smelting. Oxygen depletion of iron ore is done by reducing gases or carbon from urban gas and coal.

How large is Pakistan’s iron ore production?

The molten iron, which is purified and separated from impurities, is converted into steel by the addition of a certain amount of carbon and alloying metals such as chromium, nickel, titanium, manganese, and vanadium. Of course, special steels may also contain other metals, such as molybdenum and tungsten, which are used in certain cases. Iron and carbon together form cementite at high temperatures. Steel containing cementite is harder and more brittle than steel containing graphite. When steel containing cementite cools slowly, its equilibrium shifts to the formation of iron and carbon, carbon is separated into graphite flakes and turns gray metal. But if the steel is fast, the carbon remains in the form of light-colored cementite. In these two types of steel, the amount of carbon in it can be adjusted to a large extent. Also, the total values of carbon in different parts of steel can be changed and properties can be improved. Steel products have different sections and applications such as rebars, wires, steel sheets, pipes, etc., which are usually used in the automotive and construction industries. Steel products such as sheets, rolls, Pakistan Iron Ore Production by Year, are used in auto parts, shipbuilding, printing, packaging, and construction industries.

Domestic demand for iron ore of pakistan

This method uses scrap iron or sponge iron. Most Iranian steel is produced in this way. In Iran, sponge iron is mostly used due to a lack of iron scrap. South Steel Complex uses this method to produce crude steel. In this method, due to the use of scrap iron, the production speed is higher and the costs related to the construction of the furnace are lower than the high furnace. Electric arc furnaces are less environmentally friendly. In order to burn long furnaces, it is necessary to create heat, heat, and reduction. Long furnace fuel is divided into two categories, natural and artificial fuels. Natural fuels such as bituminous coal, anthracite, and lignite coal. Among artificial fuels, coke is more important than charcoal. And because of its properties, it is used in most factories. The benefits of fleas include difficulty, abundance, combustion, and more burning, cheapness and porosity. To make fleas, they have to mix several types of coal with different volatile substances in them and turn them into fleas in special kilns, which is called “carbonization”. The chemical composition of fleas includes 85-94% carbon and the rest includes volatile substances, ash, iron ore consumption in Pakistan, and moisture.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: