Iron ore concentrate price

The raw material for the production of iron ore is iron. Iron ore is then converted to concentrate and then pellets to steel. In this report, you will learn about the concepts of concentrate and pellets, which play an important role in the steel production chain.

How much does iron ore cost?

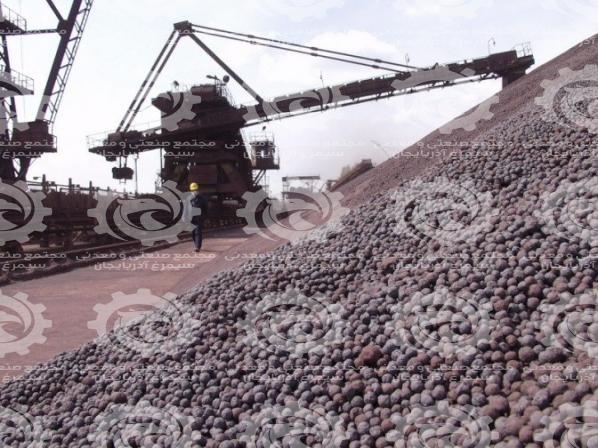

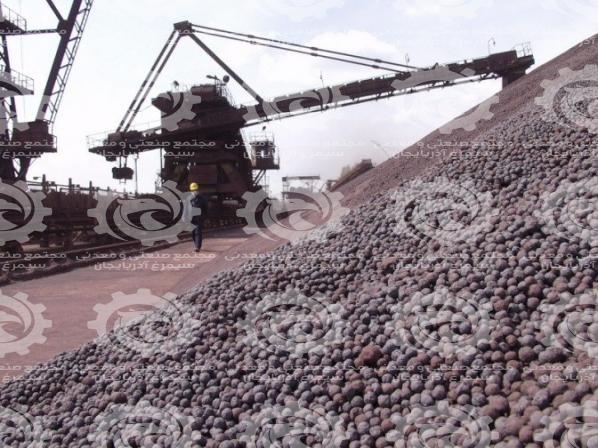

concentrate

concentrate

Since the beginning of the Industrial Revolution in Europe, the use of steel has become an essential part of the industry. With the increase in steel demand, the production of iron concentrate also increased. Iron ore processing is one of the most important processes in the steel production chain. Iron ore processing is divided into two categories based on the product produced: the production of granulated iron ore and the production of iron ore concentrate. The production of granular iron ore is done dry and without water. Then, using physical separation methods (magnetically), high-grade iron ore is separated from low-grade waste. This product, called granulation iron ore, cannot be used directly in the regeneration system due to its low grade, but it can be used in high furnaces. In deposits, the average grade of iron ore is low and the amount of excess elements is acceptable. For this reason, concentrates are produced by more advanced methods and more complex circuits.

For information about iron ore price forecast 2020 Visit our site.

Buy iron ore concentrate at affordable prices

Iron ore is the most important and major raw material for pellet production. Pellets; That is, pellets made of iron ore and other additives that are first raw and then cooked and hardened and used to revive the traditional method of iron production in blast furnaces or various direct reduction methods. Pellet is a raw material for the production of crude iron and must have good mechanical, chemical and thermal properties in regenerative furnaces. To produce raw pellets, iron ore softeners contain additives, 90% of which are below 325 mesh (equivalent to 45 microns), with rotating solutions such as water to achieve spherical shape, rotated in pelletizing machines to produce raw pellets. During the production of raw pellets, additives and adhesives such as calcium hydroxide may be added to increase the quality and mechanical metallurgical properties of pellets. At this stage, the pellets are produced with desirable dimensions and sufficient mechanical strength and are sent to the hardening or cooking machine for transport. In the second stage, the raw pellets are carefully heated in a device to harden to the softening temperature of the iron ore in order to harden and then dry, so that their degree of porosity does not decrease. At this stage, by bonding between iron ore particles and other pellet load materials, the crystalline structure of the rock changes and reactions take place between slag-forming materials and iron oxides. In this first step, the materials are exchanged and neutral compounds or games are formed between the grains of iron oxides.

For information about ron ore fines price Visit our site.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: