Direct reduction iron manufacturers

Sponge iron is a metal product that is produced by direct reduction of iron ore in solid-direct reduction iron. In other words, sponge iron is obtained by direct reduction of iron ore (Direct Reduced Iron).

Direct reduction iron various products

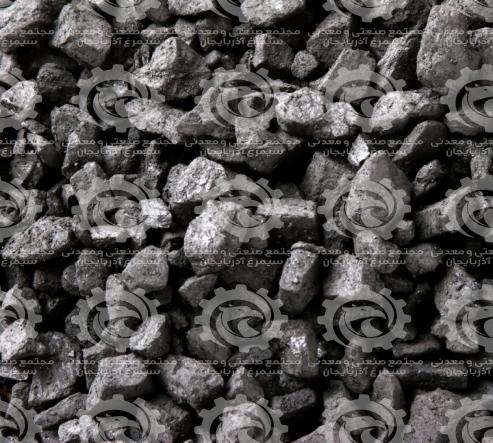

Iron ore is the pellet whose oxygen is removed following a direct (indirect) regeneration process without the need for iron ore smelting. Oxygen depletion of iron ore is done by reducing gases or carbon from urban gas and coal. The quality of sponge iron is mainly determined by the percentage of “metallization” (removal of oxygen). The appearance of sponge iron is in the form of spherical pieces (pellets) and because it has a spongy appearance, it is called sponge iron. Sponge iron has a positive effect on the production of briquettes and steel ingots in electric arc furnaces and improves energy consumption, productivity, reduced iron chemical formula, and mechanical conditions of steel ingots. Sponge iron has a high grade of iron, which is more common today due to the lack of iron waste and increasing its density, as well as environmental problems. The amount and grade of iron in sponge iron are between 84% and 95%.

Iron ore is the pellet whose oxygen is removed following a direct (indirect) regeneration process without the need for iron ore smelting. Oxygen depletion of iron ore is done by reducing gases or carbon from urban gas and coal. The quality of sponge iron is mainly determined by the percentage of “metallization” (removal of oxygen). The appearance of sponge iron is in the form of spherical pieces (pellets) and because it has a spongy appearance, it is called sponge iron. Sponge iron has a positive effect on the production of briquettes and steel ingots in electric arc furnaces and improves energy consumption, productivity, reduced iron chemical formula, and mechanical conditions of steel ingots. Sponge iron has a high grade of iron, which is more common today due to the lack of iron waste and increasing its density, as well as environmental problems. The amount and grade of iron in sponge iron are between 84% and 95%.

The high grade of sponge iron makes it a good source of iron and steel. Equipping the direct recovery unit with a cold ironing product with a hot briquette system was difficult. At this time, the importance of the technology of cold sponge iron briquetting technology became apparent, because it has more advantages than hot brittle iron briquettes, its carbon content is higher and its production costs are lower. Therefore, with the use of this technology, the process of storage and transportation of sponge iron to steelmaking units was done in a better way and the export of sponge iron in the country grew significantly.

Providing direct reduction iron from manufacturers

Today, sponge iron (DRI) is one of the most important iron sources in the steel industry, and due to the characteristics of this product, including high porosity and absorption of moisture and oxygen, high ignition conditions, mechanical durability, and abrasion resistance. Low causes the process of storing and transporting it to be difficult and therefore requires more precise safety precautions to protect it. The oxide layer forms on the surface of the snuff iron, which prevents its complete oxidation. This situation works well if there is no relocation. Because displacement and wear cause the oxide layer to separate, increasing the production softness and reducing the DRI metal grade. Sodium silicate protection and lime coatings also provide a protective layer on the sponge iron, which reduces its chemical direct reduced iron hazards. It is noteworthy that in these methods, if the SNAFJI displacement is possible, the protective layer can be separated from the DRI surface and contact with air and oxidation can occur. Significantly, the use of sodium silicate and lime increases economic costs.

Today, sponge iron (DRI) is one of the most important iron sources in the steel industry, and due to the characteristics of this product, including high porosity and absorption of moisture and oxygen, high ignition conditions, mechanical durability, and abrasion resistance. Low causes the process of storing and transporting it to be difficult and therefore requires more precise safety precautions to protect it. The oxide layer forms on the surface of the snuff iron, which prevents its complete oxidation. This situation works well if there is no relocation. Because displacement and wear cause the oxide layer to separate, increasing the production softness and reducing the DRI metal grade. Sodium silicate protection and lime coatings also provide a protective layer on the sponge iron, which reduces its chemical direct reduced iron hazards. It is noteworthy that in these methods, if the SNAFJI displacement is possible, the protective layer can be separated from the DRI surface and contact with air and oxidation can occur. Significantly, the use of sodium silicate and lime increases economic costs.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: