Direct-reducediron annual sales growth

D The sponge iron production process takes place by removing oxygen from the iron ore. The quality of the sponge iron is mainly determined by the percentage of metallization (oxygen removal). This parameter is equal to the ratio of metallic iron to the total amount of iron in the product. Sponge iron itself cannot be used alone, but it can be processed to produce molten iron. For more information direct-reducediron visit our website.

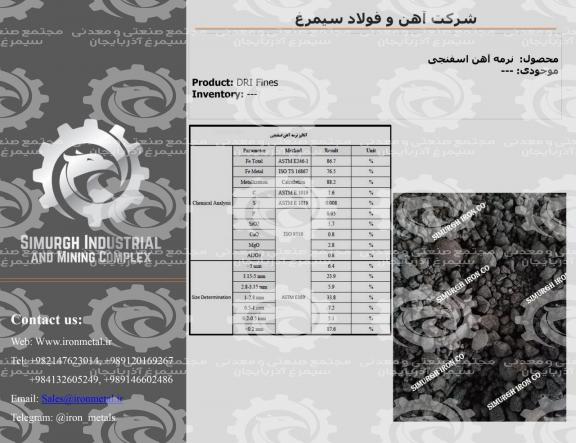

The specifications of direct-reducediron

In the direct reduction method, solid iron is obtained directly from iron oxide without the need for melting. Most direct reduction processes are gas or coal based. Direct reduction furnace feed – 10 to 30 mm iron ore or iron ore pellets. Sponge iron production is actually an alternative to furnace steel production. This product, containing over 94% iron, is melted and refined in an electric arc furnace. Since this method can be used at a lower production capacity than steel production, it is a suitable method for producing steel in volumes much smaller than a blast furnace.

In the direct reduction method, solid iron is obtained directly from iron oxide without the need for melting. Most direct reduction processes are gas or coal based. Direct reduction furnace feed – 10 to 30 mm iron ore or iron ore pellets. Sponge iron production is actually an alternative to furnace steel production. This product, containing over 94% iron, is melted and refined in an electric arc furnace. Since this method can be used at a lower production capacity than steel production, it is a suitable method for producing steel in volumes much smaller than a blast furnace.

پSponge iron is one of the most important and necessary raw materials required for the production of various iron and steel parts such as rods, pipes, etc., and also the best alternative for steel production using induction and electric arc furnaces. mills. Sponge iron is an essential product for steel companies and factories. Iran produces over 25% of the world’s sponge iron. Sponge iron is an important resource in the steel industry. It is hoped that in the coming years Iran will become one of the three leading steel-producing countries in the world.

The use of sponge iron in induction furnaces can replace up to 50% of the sponge iron, which is more economical. Of course, it goes without saying that using it in induction furnaces requires knowledge and experience. Other advantages and applications of sponge iron over scrap can be used in most steelmaking methods, which is why today many small and large steelmaking enterprises use this method. In addition, sponge iron is a very good alternative to iron scrap and scrap. Thus, in addition to using scrap as an initial melt for steelmaking units, sponge iron can be used. For more information direct-reducediron in bulk visit our website.

Annual sales growth of direct-reducediron

Annual sales growth of direct-reducediron is very good, so that in the shortest possible time, this product has opened its place among customers and buyers, and on the other hand, the reasonable price of this product has greatly affected sales, so You can visit our official website for more information about direct-reducediron trade.

Annual sales growth of direct-reducediron is very good, so that in the shortest possible time, this product has opened its place among customers and buyers, and on the other hand, the reasonable price of this product has greatly affected sales, so You can visit our official website for more information about direct-reducediron trade.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: