Direct reduced iron in steel industry

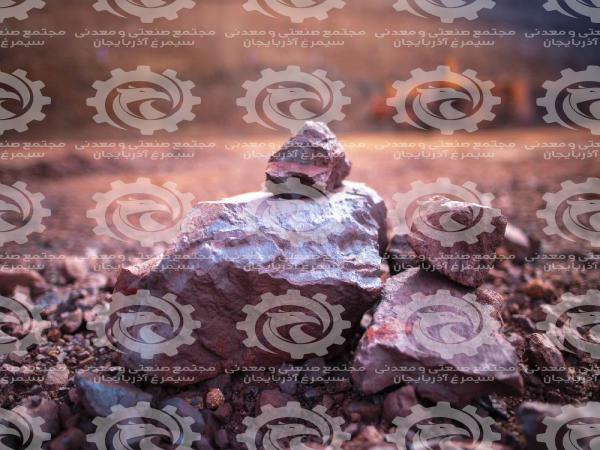

Raw iron is the raw material for making all iron and steel products. It is obtained by melting and separating iron ore, direct reduced iron in steel, and sponge iron.

Important features of direct reduced iron in steel

Most of the world’s crude steel is produced by this method. First, the iron ore is lined with lime and coke from the top of the kiln and raw iron is obtained. The iron is then converted to steel, and after the impurities are separated, the raw steel is produced. This method is used in steel. For steel production, this method is a priority over the indirect regeneration method. This method uses scrap iron or sponge iron. Most Iranian steel is produced in this way. In Iran, sponge iron is mostly used due to a lack of iron scrap. In this method, due to the use of scrap iron, the production speed is higher and the costs related to the construction of the furnace are lower than the high furnace. Electric arc furnaces are less environmentally friendly.

Most of the world’s crude steel is produced by this method. First, the iron ore is lined with lime and coke from the top of the kiln and raw iron is obtained. The iron is then converted to steel, and after the impurities are separated, the raw steel is produced. This method is used in steel. For steel production, this method is a priority over the indirect regeneration method. This method uses scrap iron or sponge iron. Most Iranian steel is produced in this way. In Iran, sponge iron is mostly used due to a lack of iron scrap. In this method, due to the use of scrap iron, the production speed is higher and the costs related to the construction of the furnace are lower than the high furnace. Electric arc furnaces are less environmentally friendly.

In order to burn long furnaces, it is necessary to create heat, heat, and reduction. Long furnace fuel is divided into two categories, natural and artificial fuels. Natural fuels such as bituminous coal, anthracite, and lignite coal. Among artificial fuels, coke is more important than charcoal. And because of its properties, it is used in most factories. The benefits of fleas include difficulty, direct reduced iron prices, combustion, and more burning, cheapness, and porosity. To make fleas, they have to mix several types of coal with different volatile substances in them and turn them into fleas in special kilns, which is called “carbonization”. The chemical composition of fleas includes 85-94% carbon and the rest includes volatile substances, ash, sulfur, and moisture.

Use direct reduced iron in steel in industry

Due to the activity of iron metal when it is in the vicinity of oxygen and moisture, the so-called “calls”. In fact, iron is formed by the formation of iron oxide, which is red and covers it. To make better use of iron and prevent it from rusting, it is galvanized. In this method, the iron is coated on the flywheel and does not rust when the galvanized iron is exposed to a humid environment. The term stainless steel is a common misconception about this metal. When carbon is added to iron, it turns into an alloy and goes out of the elemental state. This alloy is called steel, which has better properties than iron. One type of steel is stainless steel, reduced iron formula, in addition to iron and carbon, has other elements such as chromium added to it, which makes it resistant to rust. So the term stainless steel is wrong and stainless steel is correct. The air is blown at the bottom of the furnace and heated by using hot gases coming out of the top of the furnace. Coke (pure carbon), which is formed by heating coal in the absence of air, burns hot air during brewing, and carbon dioxide is formed by a highly thermonuclear reaction.

Due to the activity of iron metal when it is in the vicinity of oxygen and moisture, the so-called “calls”. In fact, iron is formed by the formation of iron oxide, which is red and covers it. To make better use of iron and prevent it from rusting, it is galvanized. In this method, the iron is coated on the flywheel and does not rust when the galvanized iron is exposed to a humid environment. The term stainless steel is a common misconception about this metal. When carbon is added to iron, it turns into an alloy and goes out of the elemental state. This alloy is called steel, which has better properties than iron. One type of steel is stainless steel, reduced iron formula, in addition to iron and carbon, has other elements such as chromium added to it, which makes it resistant to rust. So the term stainless steel is wrong and stainless steel is correct. The air is blown at the bottom of the furnace and heated by using hot gases coming out of the top of the furnace. Coke (pure carbon), which is formed by heating coal in the absence of air, burns hot air during brewing, and carbon dioxide is formed by a highly thermonuclear reaction.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: