Direct reduced iron from india price list

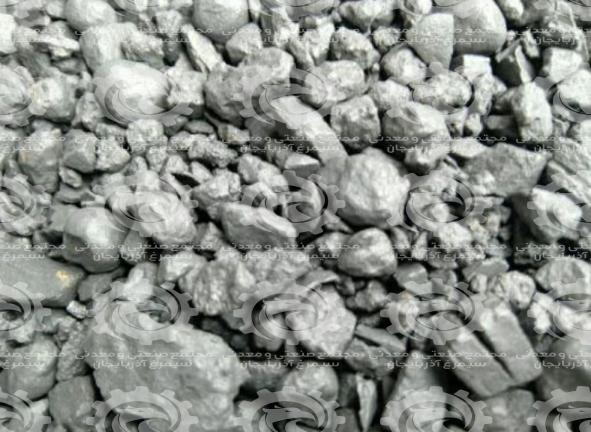

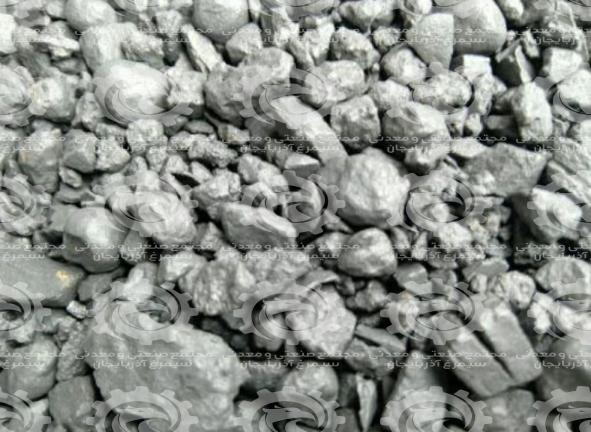

How is the export of direct reduced iron from india? Iron is not exposed to oxidation and rust. Unlike furnace cast iron, which is almost pure metal, direct regeneration iron contains some silica impurities that must be eliminated during the steel-making process.

What does direct reduced iron mean?

Directly reduced iron is not useful in itself, but it can be used to make wrought iron or processed steel. The sponge is separated from a type of furnace, called a pure iron furnace, and is repeatedly hammered with heavy hammers and rolled to form any additional impurities that form carbon oxide or carbide to boil the iron. This method of production usually produces wrought iron with about three percent impurities and a percentage of other impurities. Doing more of this may add controlled amounts of carbon and provide a variety of heat treatments. Today, with the reduction of iron ore without the melting of iron, there is a direct reduction of iron. This makes it energy efficient for manufacturers of specialized steels that rely on scrap steel and its reproduction. what is reduced iron formula? what is the use of reduced iron in food?

Latest price fluctuation of direct reduced iron from india

Factors that directly reduce the direct production of iron:

- Directly reduced iron is about the size of cast iron, typically 90-94% of total iron (depending on the quality of the ore). Therefore, it is an excellent raw material for electric furnaces used by small factories and allows them to use lower scrap for recharging or producing higher grades of steel.

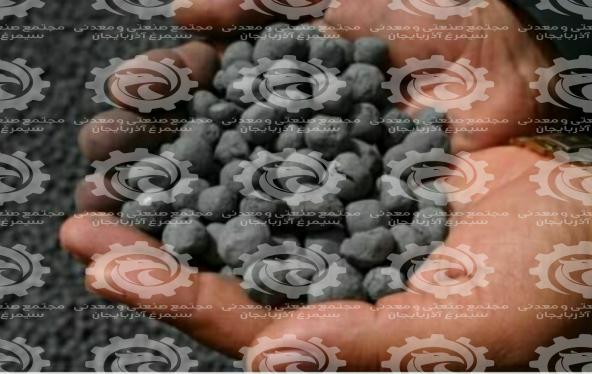

- Iron Briquettes (HBI) is a compressed form of direct reducing iron designed to facilitate transportation, storage and storage.

- Hot-dip galvanized iron (HDRI) is a type of iron with direct reduction that is transferred hot and direct from the reduction furnace into the electric arc furnace, thus saving energy.

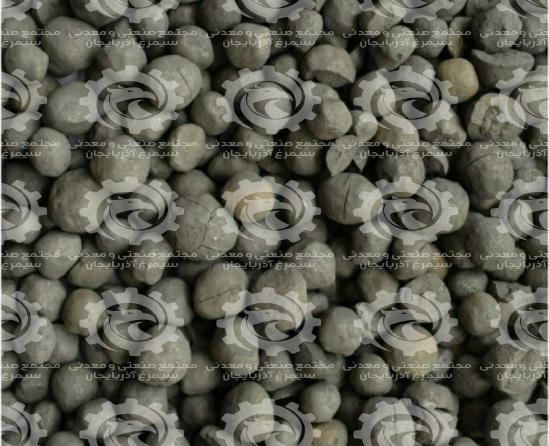

- The direct reduction process uses pelletized iron ore or “ore” natural ore. An exception is the fluidized bed process, which requires mineral iron particle particles.

- The direct reduction process can use natural gas contaminated with inert gases and prevent the need to remove these gases for other uses. However, any inefficient gas pollution in the gas reducer reduces the effect (quality) of the gas flow and the thermal efficiency of the process.

- Powdered mineral resources and crude natural gas are available in areas such as northern Australia and prevent the cost of fuel transportation. In most cases, the iron plant is rehabilitated directly near a natural gas source because it is more economical to transport the stone instead of the gas.

- The direct iron reduction method produces 97% pure iron.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: