The world’s steel trade can be energy-intensive. If you sell steel, you are familiar with the never-ending barrage of challenging inquiries.

Where can I purchase steel goods? What type of steel should I buy? How do you establish business ties and pick a dependable supplier? How to expand your export of steel.

Maintain your composure. These are your responses.

For more details, see our article on steel.

Iron, steel, brass, copper, and aluminum are commodities that are sold by the metal wholesalers to a variety of sectors. Examples include manufacturers of machinery, utilities, and construction.

The market for steel products is made up of businesses (organizations, sole traders, and partnerships) that sell steel products and make iron and steel products by rolling or drawing iron or steel and drawing steel wire. These businesses market and sell steel.

Iron, steel, and steel pipe and tube are frequently rolled and pulled. Metal-casting-rolled steel is referred to as “rolling and drawn steel.” Numerous product types are used in industries like packaging, energy, automotive, and construction. Examples include flat steel, long steel, tubular steel, steel pipes, and steel tubes.

semi finished iron companies

KG, ALU-POINT GmbH & Co.KG, AG der Dillinger Hüttenwerke, and Ambo-Stahl-Gesellschaft Gerhard Sevenich mbH & Co. are a few of the companies engaged in the production of iron ore semi-finished products.

Iron ore is processed to create iron ore materials (IOM), which are then used in the iron and steel sector. They serve as a source of iron (Fe) for the production of hot briquetted iron (HBI), direct reduced iron (DRI), ferroalloys, and pig iron in blast furnaces. Concentrate, pellets, and sinter are the three primary forms of materials made from iron ore.

Pig iron is an iron alloy made up of additional elements and carbon (>2.14 percent C). Due to its outstanding casting qualities, it is frequently utilized in steel production as well as casting for a variety of purposes.

In addition to Ferrum (Fe), carbon (ranging from 0.025 to 2.14 percent), additives, and alloys, steel is a multicomponent metal. Square billets, blooms, beam blanks, slabs, and rounds are examples of semi-finished steel products that are used to hot-roll sections, flat goods, and pipes.

Coke and chemicals both encompass finished goods that are produced in coke and chemical facilities. The principal byproduct of coking, which is the carbonization of coal at high temperatures in the absence of air, is coke, which is used as a fuel and chemical to reduce iron in blast furnaces. Coke is produced as a result of the carbonization of coal. In addition to coke, other byproducts of the processing of coal include the production of coke-oven gas, coal tar, and aromatic hydrocarbons (such as benzene and phenol). These byproducts are then taken to specialized enterprises where they are subjected to additional treatments and processed in order to produce goods such as crude benzene, benzene for synthesis, ammonium sulfate, coal tar electrode pitch, naphthalene, and many more.

finished product of iron ore

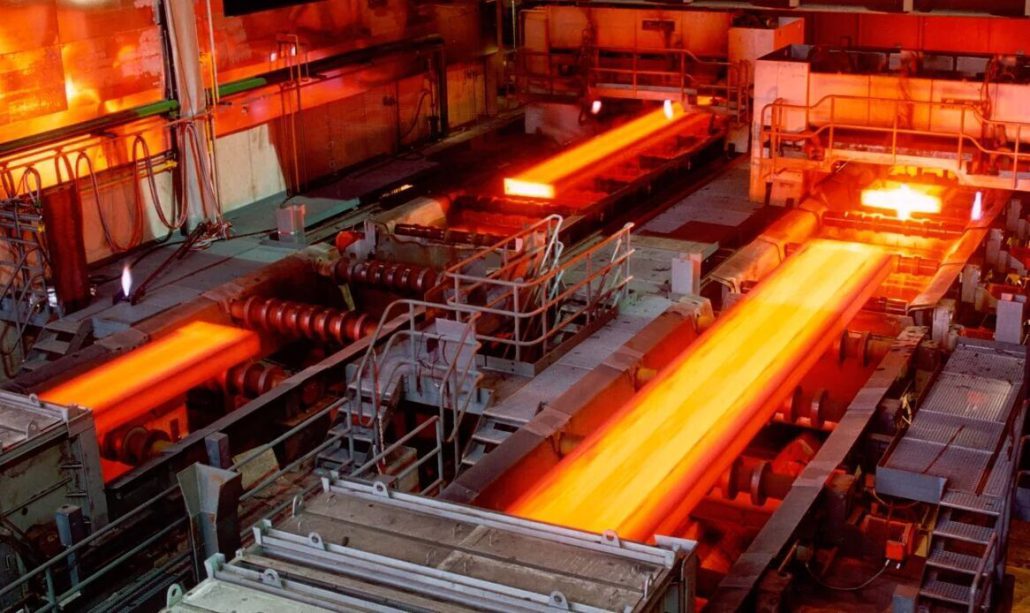

The goods made from iron ore that is produced by the steel industry are collectively referred to as completed steel products. This indicates that they are items that may be traded; more specifically, they have taken on a form that is suited for the clients of the steel business, such as those in the engineering and building industries.

Finished steel products can take many different forms, including plate, strip, rod, profile, wire, and tube.

However, there is a current movement toward steel industries producing an increasing variety of processed goods. There is a certain amount of processing or finishing that is done, such as cutting, making holes, and surface treatment, all of which have the potential to bring monetary benefits to both the supplier and the customer.

The majority of the time, consumers in society only come into contact with finished steel products after they have undergone additional processing (for more information, see the section on “End products of steel”).

It is necessary to make a distinction between steel that has been finished and commercial steel. The fact that the majority of alloyed steel used to be created expressly for specialized uses and then sold directly to the end user is probably where the names “commercial steel” and “special steel” originated. This is the first known instance of the terms’ names being used. On the other hand, a sizeable quantity of commercial steel, which is also referred to as plain carbon or non-alloy steel, was sold through the wholesale sector (steel stockholders).

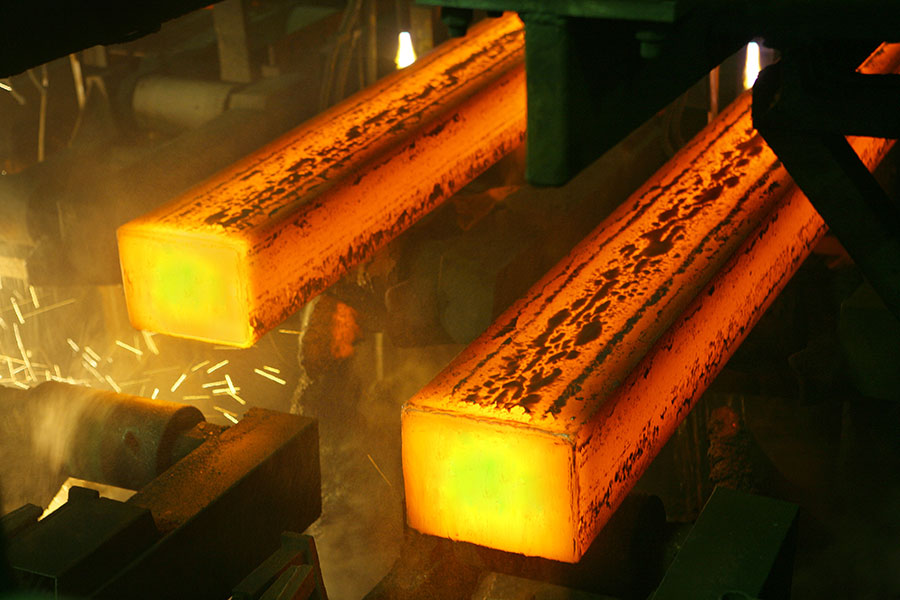

what is semi finished iron used for

After the steel-making processes are complete, a semi-finished product is created and employed in secondary manufacturing to create the finished steel items that the world demands.

By mining, processing, and enriching iron ore, iron ore materials are created at enrichment works. To generate iron ore materials of the desired size and strength, ore processing includes crushing (grinding), increasing Fe content by removing gangue and harmful impurities, drying, pelletizing, and roasting pellets.

By employing components obtained from the burning of fuel, iron oxides included in iron ore materials are reduced in blast furnaces to make pig iron (carbon oxide, hydrogen and solid carbon). Carbon-rich hot metal and slag made up of non-reduced oxides, fuel ash, flux, etc. are byproducts of the blast furnace process. Hot metal is sent to factories that make steel, foundries that make castings, and equipment that makes pig iron.

Steel is made in one of three types of furnaces: basic oxygen, open hearth, or electric arc furnaces. Each method entails the following steps: material preparation, secondary metallurgy, casting, and steelmaking at melting units. As feedstock, ferroalloys, scrap steel or iron, hot metal, or pig iron, are all used. Steel semis that are cast at continuous casting machines (casters) or teemed into ingots with additional rerolling at hot blooming or slabbing mills are examples of end products of the steelmaking process. Semi-finished goods are divided into the following categories based on their size, shape, and intended use:

Slabs are semis used to produce flats and coils. They have rectangular cross sections and high aspect ratios.

Blooms are semis designed for rolling heavy sections that have square (sides greater than 200 mm) or nearly square cross sections.

For hot rolling of medium and light sections, square billets are semis with square cross sections and sides up to 200 mm.

Semis for rolling large flange beam blanks.

Semi-rounds for making axles and seamless pipes.

finished steel products

The products that first passed the primary process and then were processed in the second phase are known as finished steel.

Completed steel products refer to all of the items that the steel industry creates from iron ore. This suggests that they are tradeable commodities; more particularly, they have assumed a shape that is appropriate for the steel company’s customers, who include those in the engineering and construction sectors.

Plate, strip, rod, profile, wire, and tube are just a few examples of the various shapes that finished steel products can take.

A contemporary trend, meanwhile, is for steel manufacturers to produce a wider range of processed items. A certain degree of processing or finishing is carried out, including cutting, drilling, and surface treatment. All of these operations have the potential to be profitable for both the supplier and the client.

Most of the time, finished steel goods are only accessible to society’s customers after going through extra processing (for more information, see the section on “End products of steel”).

Steel that has been finished must be distinguished from steel used for commercial purposes. The terms “commercial steel” and “special steel” likely came from the fact that the majority of alloyed steel used to be made specifically for specialized uses and then sold to the final customer. The names of the terms have never before been used, as far as is known. The wholesale industry, on the other hand, saw a large increase in the sale of commercial steel, often known as plain carbon or non-alloy steel (steel stockholders).

semi finished steel

Finished steel refers to the products that were initially successful in the main process and then underwent additional processing in the secondary phase.

All of the finished goods that are created by the steel industry from iron ore are referred to as completed steel products. This would imply that they are tradable commodities; more specifically, they have taken on a form that is suitable for the consumers of the steel industry, who include those in the engineering and building industries.

Steel goods that have been completed can be formed into a wide variety of shapes, including plate, strip, rod, profile, wire, and tube, to name just a few examples.

In the meantime, one of the more recent tendencies seen in the steel industry is the production of a greater variety of processed commodities. Cutting, drilling, and surface treatment are only some of the processes that are carried out during this stage of processing or finishing. Every one of these processes has the potential to generate profits for both the company providing them and the company receiving them.

Most of the time, finished steel goods are only accessible to society’s customers after going through extra processing (for more information, see the section on “End products of steel”).

Steel that has been finished must be distinguished from steel used for commercial purposes. The terms “commercial steel” and “special steel” likely came from the fact that the majority of alloyed steel used to be made specifically for specialized uses and then sold to the final customer. The names of the terms have never before been used, as far as is known. The wholesale industry, on the other hand, saw a large increase in the sale of commercial steel, often known as plain carbon or non-alloy steel (steel stockholders).

ingot vs billet vs bloom

We find the following when we compare the weights of ingots, blooms, billets, and slabs:

Blooms are lighter than ingots.

Billets are lighter than blooms.

Slabs are lighter than billets.

You want the method that will ultimately produce a product that is of the greatest possible quality when it comes to the quality of your steel products, including alloy steel. High-quality steel, which is created from semi-finished casting components, is the foundation of any high-quality product. These semi-finished casting products typically fall into one of four categories:

A particularly sizable casting product is an ingot. Depending on the final application, it typically has a cross-section that is rectangular, square, or polygonal in different sizes. It has a hot top that contributes to the ultimate product’s increased quality. It is discarded after production because it is impure, yet it is a crucial component of good ingot quality. A solid ingot with solidification properties contributes to the material’s high quality in alloy steel.

Blooms: These have cross-sections that are rectangular or square and are more than 36 square inches, or 230 square centimeters. When producing goods like seamless pipes, railroads, and many others, blooms can be used as a rolling material.

Billets: Depending on the size of the billet caster, these are typically produced using a continuous casting machine, or CCM. They have cross sections that are constant along their whole length.

Slab: Compared to bloom, a slab’s cross-section is significantly wider and less thick.

Every contemporary economy needs steel to grow; it is thought to be the foundation of human civilization. The amount of steel consumed per person is seen as a key measure of a nation’s socioeconomic development and standard of living. It is the outcome of a sizable, technologically advanced industry with reliable revenue and material flow ties in both the forward and backward directions. All major industrial economies have a thriving steel industry, and the growth of many of these economies has been largely shaped by the potency of their steel industries in the early phases of development.

Customers are the primary focus of our company, and in order to better serve them, we provide steel products in a range of styles, including semi-finished and finished varieties.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: