Superior iron pellets domestic market

The other type of Superior iron pellets is the waffle slab, which is an instrument element and has a grid-like system on it flat and low. It is usually thin and has reinforcing armatures in both directions. Roofs that consist of slab waffles are more stable and therefore are suitable for large openings.

Unique Characteristics of iron pellets

To construct this type of slab, as the name suggests, they use prefabricated plastic bubbles. Then the fortifications between and on the plastic and finally the concrete is poured fresh. The advantages of this type of slab can be pointed to the use of bubble slab in high capacities, as well as reduce weight and increase strength. In the end, it requires less pillars and no longer needs to put the rafters or bars under the roof. As a result, it is less expensive and does not cause problems for the environment due to low use of concrete.

To construct this type of slab, as the name suggests, they use prefabricated plastic bubbles. Then the fortifications between and on the plastic and finally the concrete is poured fresh. The advantages of this type of slab can be pointed to the use of bubble slab in high capacities, as well as reduce weight and increase strength. In the end, it requires less pillars and no longer needs to put the rafters or bars under the roof. As a result, it is less expensive and does not cause problems for the environment due to low use of concrete.

This type of slab is placed on steel flooring and is usually used for sturdy concrete. It’s like a framework where the construction of this slab depends on the thickness of the steel flooring. If the thickness of the steel flooring is between 50 or 60mm, the slab capacity can reach 3 meters. But if the thickness of the steel flooring reaches 80 mm, the slab can be run with a thickness of 4.5 meters.

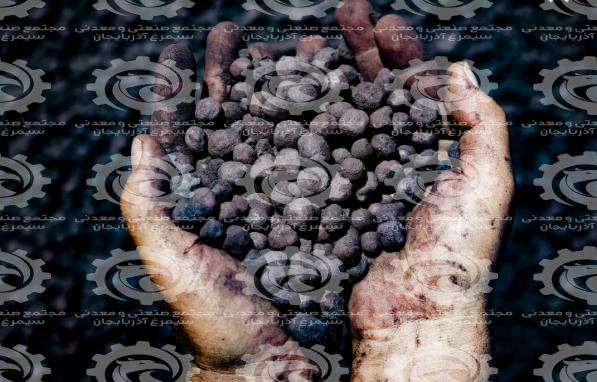

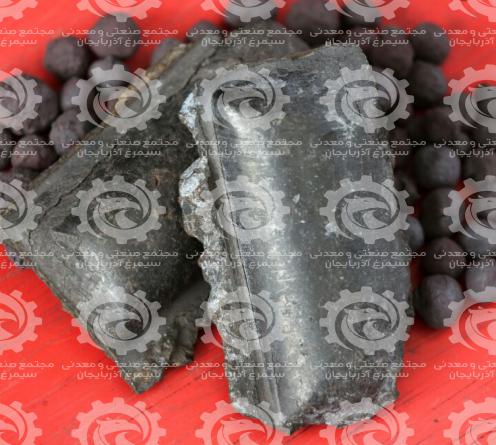

If you are working in the steel industry, you need to be familiar with iron ore pellets chemical composition and iron ore pellets manufacturers so that you can work professionally in your work. In general, pelletizing means rigid pelletizing that is produced from the soft iron ore. These pellets are soft at first and are rigid in Myrtle. Then used in the production of steel. Pelletizing is carried out using appliances such as Rotary cylinders and disks and pelletizing tank. Pellets, also known as sponge irons, are converted into concentrates before they become iron and steel. In the preparation of these products, some additives are also used. When the iron ore pellets are still soft, they are placed in the furnace tanks and ready to be baked.

In fact, pelletizing is a raw material used to prepare raw iron, which still has its own softness and turns into iron during the sintering and production process. When producing these types of products, iron should be used, which is about 70% carat. Because using these raw irons, the best and most quality type of pellets are obtained. When the employees of the steel industry, the information in their about pelletizing Iron top brand definitely can get in the industry related to their jobs and careers to good working and are of the product consumer use and crop production, steel act.

Domestic market of Superior iron pellets

Iron ore pellets are sold at different prices. But if customers intend to buy these pellets at cheap prices, they can do so in bulk. Major sales pelletizing of iron ore across the country makes the buyers of this product widely used in various industries, can be advantageous in the preparation of their. The sale of iron ore pellets in bulk from the center will help customers to buy the products they need in high volume.

Iron ore pellets are sold at different prices. But if customers intend to buy these pellets at cheap prices, they can do so in bulk. Major sales pelletizing of iron ore across the country makes the buyers of this product widely used in various industries, can be advantageous in the preparation of their. The sale of iron ore pellets in bulk from the center will help customers to buy the products they need in high volume.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: