Direct reduction iron Wholesalers

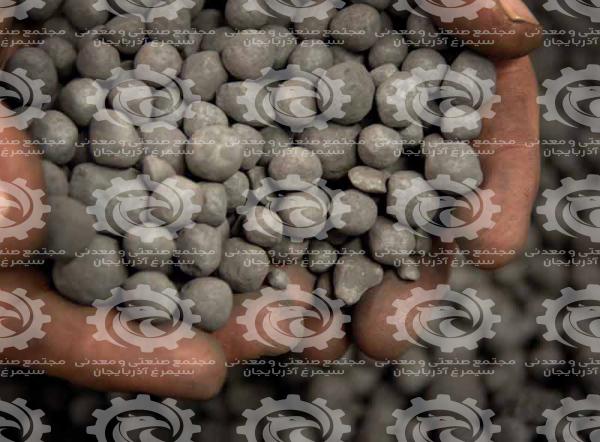

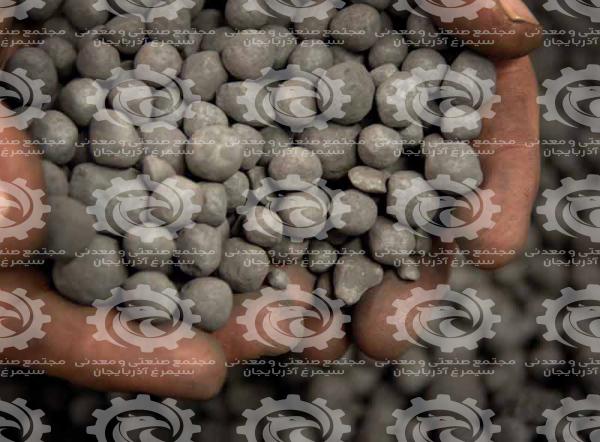

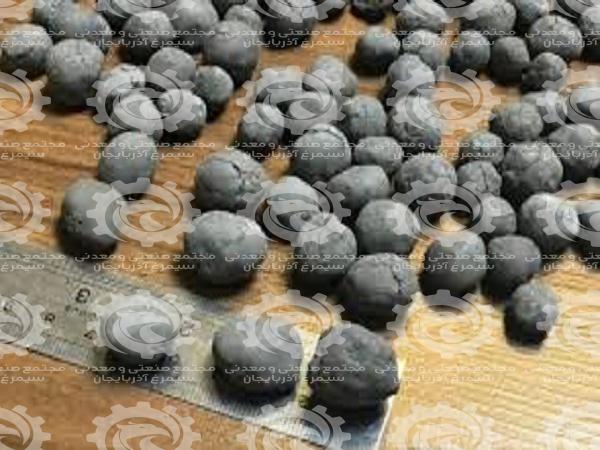

direct reduction iron is caused by the direct oxidation of minerals and is also known as sponge iron. Sponge iron is formed through various processes. These steps take place at temperatures below the melting point. During this process, iron oxides are reduced to metallic iron. direct reduced iron prices is very convenient and distributors offer this product throughout the countrys markets.

What is direct reduction of iron ore?

direct reduction process history to obtain iron was first done in the Middle East and Europe. The direct reduction process is based on two categories of gas and coal. In both methods, oxygen is extracted from minerals such as iron ore and eventually converted to metallic iron. Direct iron reduction is done by modern furnaces and traditional furnaces are not suitable for this purpose.

direct reduction process history to obtain iron was first done in the Middle East and Europe. The direct reduction process is based on two categories of gas and coal. In both methods, oxygen is extracted from minerals such as iron ore and eventually converted to metallic iron. Direct iron reduction is done by modern furnaces and traditional furnaces are not suitable for this purpose.

In developing countries, the process of direct reduction of iron has overcome the problems of conventional furnaces, and with the most modern electric furnaces, products such as steel are made. Today, this process is successfully performed in many countries around the world, and specialized steel and iron products are produced in the best quality. In direct reduction plants, operating costs are much lower than in integrated steel plants, hence this method has become common.

Thus, it can be said that iron production by direct reduction is very economical. Direct iron reduction plants are mostly built near ores. These powdered minerals are used as a raw material in this factory. The iron produced in these factories is more than ninety seven percent pure, which has many uses.

In the process of direct reduction of iron, raw natural gases and pelleted iron ore can also be used. But using ore is much more economical than natural gas. The sponge iron produced during all these stages cannot be used in the market alone. This material is used as a raw material in steel mills. Metal iron, which is made through various processes, is used in various industries. In ancient times, this metal was used to make swords and weapons, but today in the car factory, iron is used to make car bodies.

Bulk selling of direct reduction iron

Today, the process of direct reduction of iron is done by reducing iron ore, without the need for a melting step. The iron made in this method has a high grade and the reasons for its prevalence are the increase in the price of scrap iron and other problems such as environmental problems. Instead of using scrap iron, steel mills use this sponge iron because it is economically viable. Bulk purchase of direct reduction iron is possible through this center .

Today, the process of direct reduction of iron is done by reducing iron ore, without the need for a melting step. The iron made in this method has a high grade and the reasons for its prevalence are the increase in the price of scrap iron and other problems such as environmental problems. Instead of using scrap iron, steel mills use this sponge iron because it is economically viable. Bulk purchase of direct reduction iron is possible through this center .

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: