Direct-reduced iron global market

Iron and its alloys are among the most widely used and common metals, having smooth, shiny silver-gray surfaces but appearing red or brown when combined with oxygen in air. Pure iron is a metal, but despite the oxygen and moisture in which it combines, it oxidizes and can rarely be seen in the form of pure metal or iron on Earth, so to obtain iron metal by a method In the name of chemical reduction, they remove the oxygen contained in the ore and thus the iron metal is formed. For more information about Direct-reduced iron global market, visit our site.

The brief introduction to direct-reduced iron

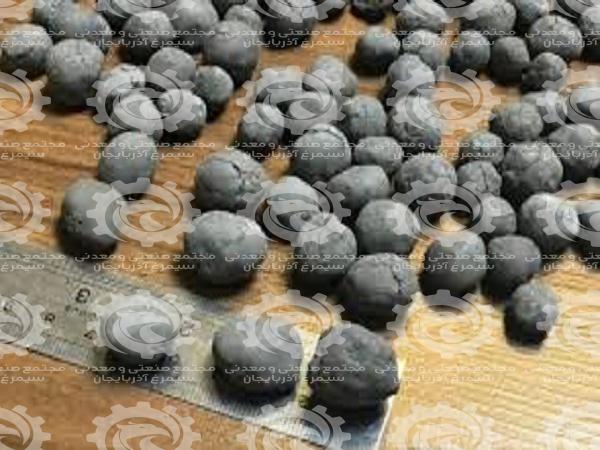

Iron is produced from hematic ores, denoted by the symbol Fe2o3. This ferrous metal is separated by large furnaces with temperatures above 2000 ° C by the carbon reduction method and the iron metal is extracted. Iron ore mining is generally carried out in 48 countries, including China, Brazil, Australia, Russia and India, which are five countries that extract and produce 70% of the world’s iron ore. Iron is the sixth most abundant element in the world, but is the fourth most abundant element in the Earth’s crust. Scientists believe that the Earth’s core is largely composed of iron-nickel alloy, which accounts for 35% of the total mass. It forms the earth, so iron is one of the most abundant elements on earth for these reasons, and among metals, 95% of the metal is iron production. By using the properties of iron and other metals and their combination, we can achieve steel.

Iron is produced from hematic ores, denoted by the symbol Fe2o3. This ferrous metal is separated by large furnaces with temperatures above 2000 ° C by the carbon reduction method and the iron metal is extracted. Iron ore mining is generally carried out in 48 countries, including China, Brazil, Australia, Russia and India, which are five countries that extract and produce 70% of the world’s iron ore. Iron is the sixth most abundant element in the world, but is the fourth most abundant element in the Earth’s crust. Scientists believe that the Earth’s core is largely composed of iron-nickel alloy, which accounts for 35% of the total mass. It forms the earth, so iron is one of the most abundant elements on earth for these reasons, and among metals, 95% of the metal is iron production. By using the properties of iron and other metals and their combination, we can achieve steel.

Alterations: Iron is perhaps the best known example of metamorphosis in a metal. There are three forms of polymorphism called allotropes, stenite and ferrite. This is how the name can be explained: As the molten iron cools slowly, it crystallizes into allotropy at 1538 ° C, also known as delta iron, and has a central cubic crystal structure. During further cooling, the crystalline structure changes to a cubic face at a temperature of 1394 ° C, which is called a form of austenitic iron or gamma iron, and at a temperature of 912 ° C, the crystalline or crystalline structure becomes a cube again, which ferrits this transformation. Or it is called alpha iron, which is crystalline very similar to delta iron.

Iron is known to be the most common and widely used metal in the world because 95% of the metals produced in the world are iron. This is such that iron with high impact strength is one of the cheapest metals and always It has been used in the skeletons of buildings, car hulls and the hulls of large ships. In general, products made from crude iron can be divided into the following categories: Cast iron: When crude iron is melted, it is poured into sand or metal frames and cooled to obtain cast iron. Magnesium and iron silicate and carbon crystallization are obtained by obtaining malleable cast iron. White cast iron: It is obtained from cooling the melt. The carbon of this cast iron is semantic carbon. Its fragility can also be reduced by softening it. For more information about direct reduced iron technology, visit our site.

Global market for direct-reduced iron

To prepare elemental iron, its impurities must be removed by chemical reduction. Iron is used to make steel, which is not an element, but an alloy and a mixture of different metals (and some non-metals, especially carbon). For more information on direct reduced iron production and Global market for direct-reduced iron, visit our site.

To prepare elemental iron, its impurities must be removed by chemical reduction. Iron is used to make steel, which is not an element, but an alloy and a mixture of different metals (and some non-metals, especially carbon). For more information on direct reduced iron production and Global market for direct-reduced iron, visit our site.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: