Iron ore exporting countries

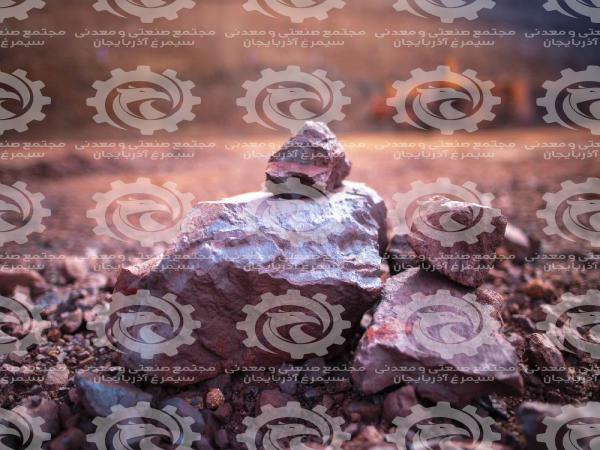

Sarmak iron ore is produced in the form of hematite and is extracted from Malayer blacksmith’s mine and is very suitable for use in cement industries. For this purpose, iron ore produced in two ranges (0-40) mm and (0-300) mm is offered. During the last 30 years, more than 25 major cement companies in Iran are the buyers of iron ore from Sarmak Mines Company.The iron ore of Sarmak Mines Company is of low grade hematite type and is used only by the country’s cement industry.

Four types of iron ore

The production method is that the mines are extracted from the mine with the great efforts of experienced workers and technical experts in the field of geology, exploration and extraction and by spending time and money from the Ahangaran mine located near Malayer city in Hamadan province directly from the mine. And after crushing to a certain extent, it is offered directly to the market. This activity has created employment for more than 200 hardworking personnel and employment of about 100 truck drivers to transport to the country’s cement factories and we are proud of God Almighty as a powerful arm for industry. We achieved this by relying on the efforts of compassionate managers and hardworking staff and the application of technical and engineering knowledge.

Iron ore analysis of Sarmak Mines Company is attached.

What is iron ore?

Iron ore is a type of mineral that contains iron metal. The chemical symbol of iron is Fe. Iron ore is extracted from iron ore mines. Iron ore in different mines differs in appearance and internal structure. Iron ore is composed of various minerals, the most important of which are magnetite and hematite….

For information about iron ore prices Visit our website.

Main exporting countries for iron ore

Iron ore is the most important raw material for iron and steel production. In general, most iron ore is used in the traditional method of iron and steel production (blast furnace / converter) and only a small part of it is used in other methods, especially direct regeneration, so that the total amount of iron ore extracted in the world It takes less than 10 percent to be used in direct recovery and more than 90 percent to be used in a long furnace.

The specifications required for iron ore vary depending on the type of consumption and the area of production and supply. For example, iron ore, which can be used well in the traditional method, may not be able to be used directly in direct regeneration methods, or the specifications required for the use of red soil in dyeing are completely different from its metalogical uses. Thus, it is observed that not only the necessary specifications for iron ore in different uses but also different points are not the same, even for each long furnace or direct recovery method, the specifications of iron ore must match the type of furnace, its capacity, height, etc. . Table 2-1 shows the main materials needed to produce a ton of steel.

For more information about iron ore chemical formula Visit our site.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: