Direct iron reduction local supplier

The first iron formed by humans in prehistoric times came from meteorites. Iron has a smooth surface and shiny silver-gray, but when combined with oxygen in the air, it turns red or brown, which is called oxide, which contains iron or rust compounds. Iron is the sixth most abundant element in the world. In this article, we will write about direct iron reduction.

How direct iron reduction is produced?

The Sumerians and Egyptians were the first signs of the use of iron, which was discovered with iron almost “4,000 years ago” and produced small items such as spearheads and ornaments from meteorites. From 2000 to 3000 BC, a number of objects were made that distinguish these products from meteorites with molten iron. Iron extraction from natural iron compounds has evolved over time, until the first iron ore furnace in its modern style, known as the Annie Channel furnace, was unveiled.

The Sumerians and Egyptians were the first signs of the use of iron, which was discovered with iron almost “4,000 years ago” and produced small items such as spearheads and ornaments from meteorites. From 2000 to 3000 BC, a number of objects were made that distinguish these products from meteorites with molten iron. Iron extraction from natural iron compounds has evolved over time, until the first iron ore furnace in its modern style, known as the Annie Channel furnace, was unveiled.

Most of the world’s crude steel is produced by long furnaces. In the indirect recovery method, which is also used in steel. The direct iron regeneration method is more justifiable than steel furnace production. Iron or sponge iron scrap is used in the electric arc furnace method.

The act of generating heat and the act of reducing it are two actions in the fuel of a long furnace and are divided into two main categories, natural and artificial. Some natural fuels, such as anthracite coal, bitumen and lignite, are more historical than economic, and among the artificial fuels, coke is more important than charcoal and is used in most factories. if you want more in formation about commercial hot briquetted iron see site and online stores.

Supplying direct iron reduction for markets

In 2000, approximately 1,100 million tons of iron ore were mined, with a trade value of approximately US $ 25 billion. Iron ore is mined in 48 countries.

In 2000, approximately 1,100 million tons of iron ore were mined, with a trade value of approximately US $ 25 billion. Iron ore is mined in 48 countries.

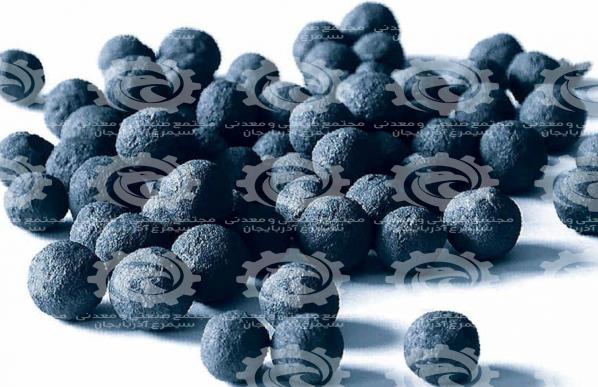

The size and type of iron ore granulation is very important for use in high quality steel kilns. For complete restoration of iron ore, the minimum grain size used in blast furnaces should be 10 mm. Every day, 2,000 tons of iron ore in special factories are granulated by three vibrating sieve machines and sent to agglomeration and blast furnace sections.

These days, the iron market fluctuates several times over a one-day period. Most of the needs and consumption of construction structures are in the form of rebars and beams. The steel mafia market is leading to price changes.

As an intermediate product, iron is still unknown in global markets, so that it is not priced on any of the reference sites of the ironworks. you can find direct reduced iron prices in this article.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Call number:

Call number:  Whats app:

Whats app:  Address: Salimi industrial Park, Tabriz, IRI

Address: Salimi industrial Park, Tabriz, IRI Instagram:

Instagram:  email:

email:  Facebook:

Facebook: